Consultant engineers are increasingly tasked with designing data center systems that can adapt to rapidly evolving operational demands - even the ones of the future which are not known today. As global data volumes increase, the resulting heat loads from high-performance computing equipment in today's data centers present a growing challenge. Achieving precise temperature control without compromising energy efficiency is becoming a central design priority.

Next to this come rising energy costs, new and stricter sustainability regulations, and the prevalence of aging cooling infrastructure - all of which demand smarter, more adaptable solutions. To meet these demands, engineers must integrate flexible cooling architectures that support scalability, ensure thermal resilience, and align with long-term effici-ency goals. The focus is shifting from traditional, fixed-capacity systems to dynamic, demand-driven cooling strategies that maximize performance while minimizing environmental impact.

This FlowCon Topic Letter will give you insights that will help you through data center design challenges by being aware of customization and the choices you have as a customer. Obviously, it is essential also to consider ΔT, installation flexibility as well as sustainability compliance when designing for long-term efficiency and future-proof concepts. These aspects are discussed in detail in other FlowCon Topic Letters.

Efficiency

- much more than energy savings

In modern data center projects, true efficiency extends far beyond energy metrics. It also involves the ability to customize solutions based on site-specific requirements and project constraints.

Custom material

FlowCon’s threaded valves are standard made of brass and the flanged range ductile iron, but we also offer a wide range of stainless steel valves from pre-set max. flow limiters, over adjustable dynamic balancing valves to pressure independent balancing and control valves, PICVs. This gives the freedom to specify materials that align with performance, durability, or sustainability targets.

Product flexibility

FlowCon valves adapt to your specific setup, ensuring long-term performance, reduced energy consumption and lower operating costs - and you choose if external adjustable flow setting, or tamper-proof pre-setting is better for your application. Either way, the result is optimized efficiency during all phases from design, installation, service and maintenance and even to proper material sorting at the end of product life.

Tailored logistics

FlowCon can arrange split deliveries, just-in-time shipments, and precise coordination with construction schedules. Respecting tight installation windows and ensuring on-site delivery within the defined time slot are not just logistical concerns; they are critical factors in maintaining project momentum and avoiding costly delays. For mechanical contractors, this means working with partners who not only deliver high-performance solutions but also offer the operational flexibility to support efficient execution from design through commissioning.

Tip:

Work with experts who understand cooling in data centers and who can assist you in designing and running a system that fits your requirements, not the other way around.

In short, efficiency must be understood in its widest possible sense: a combination of energy performance, design adaptability, material selection, product flexibility and logistical precision. This holistic approach is key to delivering future-proof data center infrastructure that meets both current and emerging demands.

Looking for Expert Support?

We know that every data center is different, so a one-size-fits-all approach does not work - and therefore FlowCon works differently. Our R&D department's knowledge runs deep, and we cover the full valve size-range needed for data centers. Based on our years of know-how we recognize the importance of user-friendliness and optimal valve performance, but also the ability to adjust to customer needs. And our logistics department are specialists in securing on-time delivery where and when you want.

At FlowCon, we strive to be more than just a supplier - we aim to be your trusted partner. By working closely with our clients, we co-create customized solutions that align with specific project demands, focusing on long-term performance and operational efficiency rather than one-size-fits-all products.

FlowCon 最新文章

显示所有文章

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

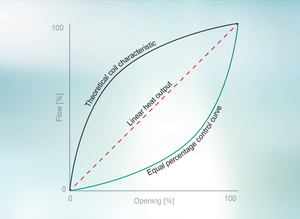

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

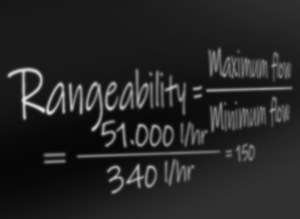

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs