What is Glycol?

Glycol is an organic compound that contains multiple hydroxyl (-OH) groups and is also known a dihydric alcohol. The most common type of glycol used in HVAC applications is ethylene glycol or propylene glycol. Propylene glycol is considered less toxic than ethylene glycol, making it a safer choice for applications where there is a concern about environmental impact.

This Topic Letter focuses on how to determine your glycol mixture flow correction factor for your HVAC application. But the Topic Letter will also give you information about why glycol is used.

Why use Glycol?

Glycol is first and foremost used as an anti-freeze additive. In colder climates, water in the HVAC system can freeze, causing damage to valves, pipes, pumps, and other components. Glycol has a lower freezing point than water, providing freeze protection and allowing the system to operate in sub-freezing temperatures.

Glycol is also seen used as a corrosion inhibition. As glycol solutions often contain corrosion inhibitors, this will help protect metal components in the HVAC system from corrosion and thereby extend the life of the equipment and maintaining system efficiency.

In some cases, glycol can also improve heat transfer properties. While water is an excellent heat transfer fluid, glycol can be added to water to modify its thermal properties. However, it's important to note that high concentrations of glycol can reduce heat transfer efficiency, so the water/glycol mix needs to be carefully balanced.

Glycol is considered harmless to most materials. To all materials used in FlowCon valves, glycol will not have any harmful effects, indifferent if used as a water/glycol mixture or 100% glycol. But glycol will affect the viscosity of the flow medium and thus also the flow itself, as it becomes 'thicker' and therefore flows more slowly. It should also be noted that the concentration of glycol added to the HVAC system will impact on the pumping power required. Particularly at low pump pressures, flow problems can arise at high glycol concentration due to the relatively large change in specific gravity…

Glycol Mix and the Flow Correction Factor

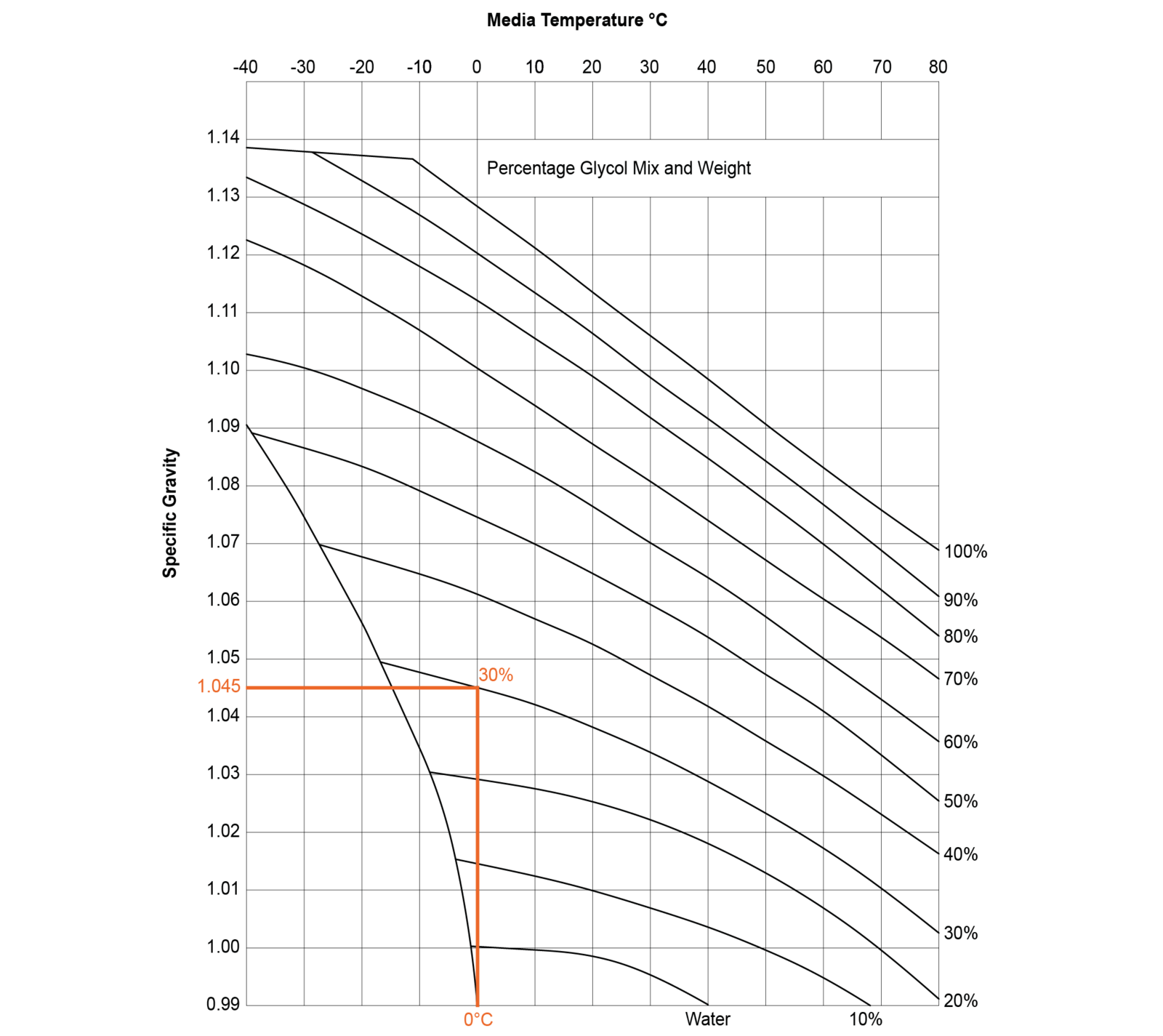

If using glycol, it is FlowCon’s recommendation to check the graph below for an adequate flow correction factor. Such flow correction factor should be based on media temperature and the percentage of glycol.

How to read the Flow Correction Factor Graph:

- What is the % of glycol?

Select the curve appropriate for your selected water/glycol mixture. The mentioned percentage refers to the concentration of glycol in the fluid

- What is the media temperature in °C?

On the top scale, select the appropriate media temperature and then identify the intersection with the glycol mix curve

- What is the flow correction factor?

Draw a horizontal line from this intersection to the left axis and determine the specific gravity. This will correspond to the flow correction factor.

Glycol Mix Calculation Example

A 0°C media with 30% glycol should provide a required flow of 2.7 l/sec. Flow correction factor is determined to 1.045 (see orange lines in the graph above).

For a Diaphragm Design, e.g. FlowCon Green.3 DN40/50, a flow rate of 2.7 l/sec would equal setting 3.2. But with 30% glycol at 0°C, setting should be adjusted. The required flow is multiplied with the flow correction factor → 2.7 x 1.045 = 2.82 l/sec. Consequently, the valve should be set to 3.35.

For a Moving Cup Design, e.g. FlowCon K DN40/50, a flow rate of 2.7 l/sec would equal a F3C2466 stainless steel insert providing 2.78 l/sec. The required flow is multiplied with the square root of the flow correction factor → 2.7 x √1.045 = 2.76 l/sec. Still, the F3C2466 insert will be the valid choice.

Need more Information ?

Contact FlowCon for more information or help in how to determine your flow correction factor.

FlowCon 最新文章

显示所有文章

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

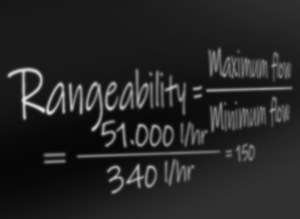

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs