This Topic Letter's focus is on key parameters to consider when choosing a failsafe actuator for your Pressure Independent Control Valve (PICV) application.

Failsafe actuators will basically ensure that the PICV can operate for one cycle when disconnected from power (either closing or opening of the water flow). Hence, based on the application, project designers can predetermine which valves to open and which valves to close during power failure, so that they can operate critical areas by using a standby power source like a generator for the chillers- and pumping system.

In general, there are two main categories of failsafe actuators. One is the mechanical failsafe actuators and the other is the power back-up failsafe actuators.

The mechanical failsafe actuators come in two ver-sions, the thermal version with a thermally sensitive material which changes physical size with the presence of electricity and the spring-loaded version which, in case of power failure, is designed to apply a force in the opposite direction of the desired motion of the actuator. The power back-up actuators commonly come with either super-capacitors or a rechargeable battery pack.

Power back-up solutions are generally recommended being used in the waterborne part of the HVAC systems as the spring return option holds restrictions in terms of performance, system accuracy and lifespan, whereas spring return options are more suitable for fast acting requirements, such as damper applications on the air side.

On the waterborne side of a HVAC system, failsafe function is urged to operate gradually to avoid water hammering, pipe vibrations and noise.

Due to this, FlowCon will not recommend installing spring return actuators on PICVs. Commonly, FlowCon proposes PICVs with electrical power back-up failsafe actuators. These are, depending on valve size, with super-capacitors (for the threaded valve sizes DN15-DN50, ½"-2") or a rechargeable battery pack (found on our flanged valve sizes DN50-DN250, 2"-10").

Thermal Failsafe Actuators

The thermal actuator is designed to convert thermal energy into mechanical motion and its fundamental principle is the expansion and contraction of commonly wax inside the element based on temperature variations. The integrated electrical resistor generates heat when electrical current flows through it and thereby produces the required temperature change needed for the actuator to operate.

With their low cost, these actuators are preferred in ON/OFF applications, but their use is limited in such analogue applications as they are also affected by ambient temperature.

Spring Return Failsafe Actuators

Spring return actuators are common in single turn actuators, including linear actuators utilizing a single turn gear, whereas many FlowCon PICV actuators are multiturn op to 3.600° for superior rangeability. It is standard practice to use springreturn actuators in damper applications, but it is not recommended using fast acting spring return actuators in chilled water systems due to several reasons mentioned below:

- The spring return actuators are generally fast acting, which may impose water hammering, which again could lead to damage of the installed valves and other installed components and may also enforce pipe vibrations.

- Spring tension will change depending on the spring elongation providing an uneven force distribution, which may impact position accuracy.

- Furthermore, spring return actuators are not very accurate in their positioning as the spring coeffi-cient will change over the lifespan of the product, reducing both accuracy and failsafe performance.

- Force is inappropriately distributed as the spring is generally strongest in fully open position (fully elongated), where the spring force is not really needed and weakest in the failsafe position (fully compressed), where you in fact will require the force.

- The actuator motor needs to work against the spring stress, which would cause increased actuator torque and thereby also increased energy consumption.

- Large size spring return actuators are generally noisy and not recommended for comfort air-conditioning applications.

Based on the above, it is not our recommendation to use spring-return actuators in the waterborne side of a HVAC modulating system.

Super-capacitor Failsafe Actuators

In terms of durability, a super-capacitor is a highly reliable electrical component, which would continue to work for many years.

The basic idea behind a super-capacitor failsafe actuator is to use the energy stored in the super-capacitors to perform a ‘last’ critical function when there is a power failure.

Besides being reliable, the super-capacitors recharge almost instantly, meaning that it will be practically impossible to discharge in a HVAC installation.

The super-capacitor failsafe actuators from FlowCon are used on the FlowCon Green/GreEQ PICV valve range. The actuators (both standard, failsafe and BACnet / Modbus versions) are linear stroke actuators which provide full control and high resolution in combination with these small PICVs.

Battery Failsafe Actuators

The battery pack used by FlowCon is designed and tested for minimum of 1000 failsafe cycles, so this also has proven and documented high reliability. In fact, for more than 10 years FlowCon has not replaced a single battery pack on any of our battery failsafe actuators supplied to projects around the world.

A failsafe actuator with a rechargeable battery pack is designed to provide reliable operation in case of power failure to operate the valve to either fully open or fully closed position. Actually, it also has the option to leave the actuator in the current position if power is lost.

The Battery failsafe actuators from FlowCon are used on the FlowCon SM PICV valve range. The actu-ators (both standard, failsafe and BACnet versions) are multi-rotation actuators and they hold up to 3.600° rotations. This results in substantially more position points than with a conventional 90° actuator and thereby also higher accuracy in performance.

It is worth noticing that the battery condition is available on both the actuator display and directly in the BMS system if BACnet versions are chosen. This way battery life can be monitored either during regular system service or automatically with built-in alarms to ensure that failsafe functionality is always optimal regardless of the actuator age and past operations.

Conclusion

Choosing the optimal actuator for the application in question is important. Having mentioned various aspects concerning the choice of failsafe actuator for any PICV application it is FlowCon Interna-tional’s clear recommendation to use either linear or multiturn actuators with power back-up on PICVs for failsafe applications. This will ensure utilization of the full working potential of the PICV valves, which will obtain the best energy efficiency and building carbon footprint, while providing optimal system protection.

FlowCon hopes that this Topic Letter has given insight to the topic. Please feel free to contact FlowCon for further assistance or any clarification.

FlowCon 最新文章

显示所有文章

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

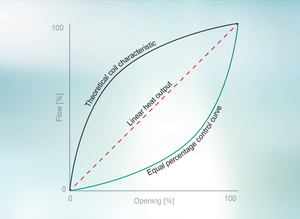

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

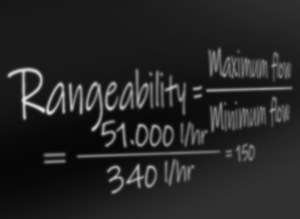

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs