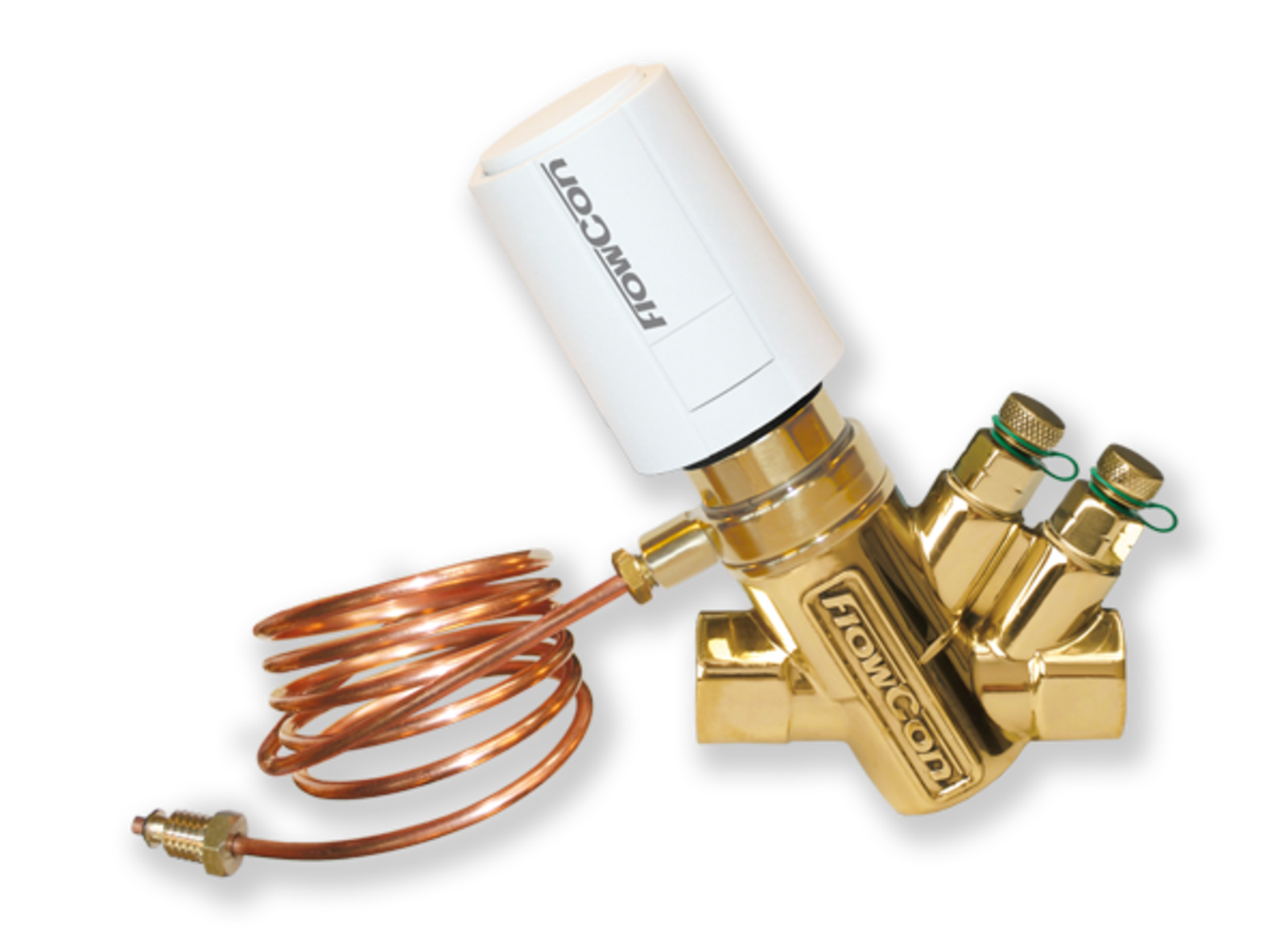

The new FlowCon ADP is designed to ensure that neither the maximum flow nor the maximum differential pressure across the controlled circuit is superseded. The differential pressure limiting functionality is implemented to prevent potential noise across the controlled circuit and will therefore eliminate the requirement of a separate DPCV in the installation. All in all the ADP can substitute the differential pressure control valve, dynamic balancing valve and the control valve reducing investments costs and installation time.

Low Energy costs

There are many motivations to reduce the system pressure drops. Reducing component pressure drop reduces the system energy consumption, which ultimately will result in financial cost savings to the building users. The new ADP operates with a working pressure of 15 kPa, ensuring the lowest energy consumption available in the industry.

Easy

The FlowCon ADP is very easy to adjust. Just use the adjustment scale on the top and select the flow required in your system and the valve will do the rest.

FlowCon ADP offers:

- 3 in 1 solution. Installing one valve with 3 functions combined will reduce purchase costs and installation time.

- Noise protection. Differential pressure control protects control valves from too high differential pressure.

- Pressure rating PN25 highest in the industry.

- Insert solution, giving multiple advantages during installation, flushing and maintenance.

- The ADP insert can be replaced if for some reason needed – and is easy to service.

- Low pressure drop starting at 15 kPaD, which are the lowest in the industry

- Flow rate 9-680 l/h. The ADP is possible of adjusting systems with very low water flow requirements.

- Fast responding mechanical components allowing rapid response to system changes.

- No special tools are required.

The valve offers adjustment with 41 different setting indications between minimum and maximum. Further, this compact ADP solution will match FlowCon actuators providing options for thermal control.

FlowCon 最新新闻

显示所有新闻

Upcoming Webinar

How to keep ΔT under control in high-load data centers

December 4th 2025, 13.00-13.45 CET

NEW SM actuator range for FlowCon SM PICVs

Wider flow range, new failure actions and programming port.

We say: the SAME but MORE

New massive T4 at Urumqi International Airport, China

Precise control, easy commissioning, scalability, efficiency, and lower operating costs is why FlowCon was selected

FlowCon publishes yet another EPD – now for PICV-actuators

The EPD covers the FlowCon FN, FH, FT, and SM ranges

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design