Pressure Independent Temperature Control (PITCV)

Pressure dependent ΔT Valves – also commonly known as energy valves – are getting known in the market. But why not take it one step further and combine both Pressure Independency and ΔT control in one solution? With the energy system solution from FlowCon you will get exactly this…

Welcome to FlowCon Energy FIT System.

With the FlowCon Energy FIT System you will get monitoring, measuring, connectivity and control in one package. FlowCon FIT measures energy usage while monitoring coil performance and adjusts the PICV valve to optimize coil performance. The solution will maintain the correct flow, despite pressure changes and will guarantee that flow change and change in actuator position only occur when demand requirements change or ΔT is outside specification. By optimizing ΔT, flow rate requirements may be reduced resulting in energy savings, while having pressure independency and ΔT control.

#YourEnvironmentOurCommitment

Why choose a Pressure Independent Temperature Control Valve (PITCV)?

The FlowCon Energy FIT System controls the valve and knows to open of close the PICV based on actual ΔT measured across the coil. When system pressures change, the PICV will absorb the pressure fluctuation and maintain constant flow which keeps the ΔT steady. This provides a pressure and temperature independent solution which will reduce actuator ware, increase PICV and coil life, and keep energy consumption at a minimum.

How does a Pressure Independent Temperature Control Valve (PITCV) work?

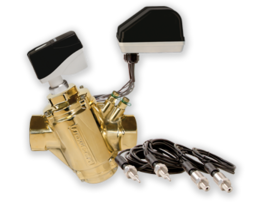

FlowCon FIT is a full package including a PICV, an Intelligent Interface and a sensor kit incl. 2 temperature sensors and 2 pressure sensors.

• PICV

The PICV is a 3-in-1 valve combining control, balancing and differential pressure control.

It is a true PICV with full authority based on input from the Intelligent Interface. Max. flow setting is done directly on the programmable display actuator.

• Intelligent Interface

The heart of the FIT system is the Intelligent Interface. It is collecting sensor information and collecting and distributing information from and to the PICV actuator and BMS system.

• Sensor kit

The included temperature sensors continuously measure the ΔT across the coil and the included pressure sensors continuously measure up- and downstream pressure of the PICV allowing the BMS to lower system pressure to the PICV’s minimum requirements and reduce pump energy consumption.

During reduced load (either due to room temperature changes OR when the thermostat is adjusted) the coil air flow will change resulting in ΔT change. The temperature sensors will read the change in ΔT and the Intelligent Interface controlling the PICV will adjust the valve to get back at ΔT target.

Questions?

Then Give Us a Call

If You have any questions, either in regard to FlowCon's products and services or how and where to use FlowCon products, just get in touch and we will be pleased to assist.

We will react as soon as possible, and written reply is normally within 8 hours if Your question is asked in English and during office hours. Other languages and requests asked during vacation time or weekends may experience longer response time. Likewise, for any special – out of standard – requests, You may not see an immediate reply, but we are responsive.