Differential Pressure Control Valves (DPCV)

in Cooling Applications

How do DPCVs benefit your Cooling Application?

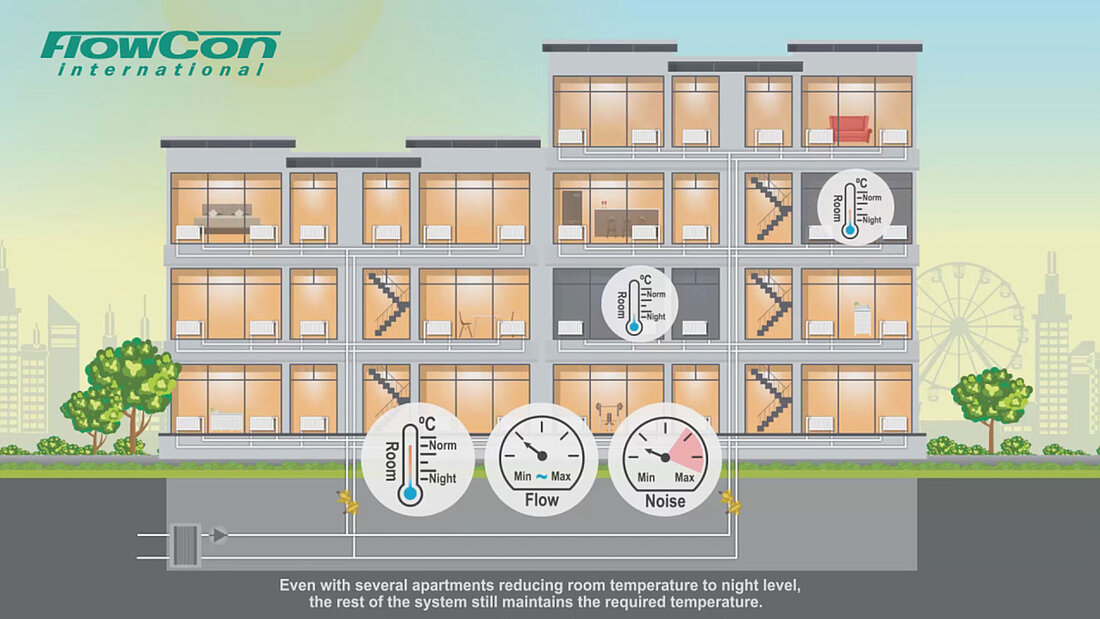

Differential Pressure Control Valves - also commonly called DPCVs - are installed in cooling systems to control sub-circuit pressure to a set or given maximum which also limits the flow at full load.

FlowCon offers here the version with adjustable ΔpC setting (ΔpC is differential pressure control across the circuit). For the smaller pipe sizes we suggest FlowCon EDP and for the larger sizes, the FlowCon PIM™-DP.

What makes FlowCon’s DPCVs superior?

A good DPCV will control the differential pressure dependent on current load.

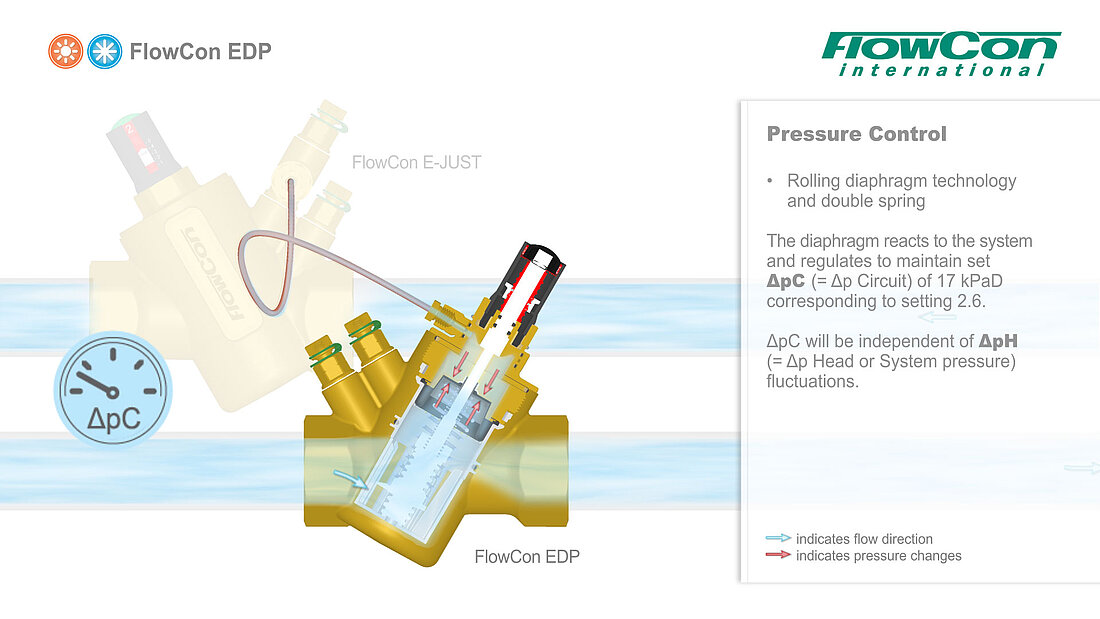

FlowCon offers a well-proven DPCV insert design with patented rolling diaphragm technology in a compact and robust design. The internal rolling diaphragm and the diffusion zone reduce the influence of cavitation during operation, which consequently reduces the possibility of noise and vibration.

And the composite material of the DPCV insert body makes it difficult for particles to stick. This, together with the self-cleaning functionality, makes FlowCon inserts resistant to dirty water.

Special benefits with FlowCon DPCV inserts

The unique FlowCon DPCV insert range (FlowCon EDP) is an adjustable ΔpC controller. It is available in the full threaded pipe range and offers flexibility through the adjustable ΔpC setting and 360° turning of connection point which gives best value-for-money.

Common for all FlowCon’s inserts are essential benefits such as:

- Simple flushing, as full force flushing forward and backward is possible without the insert present.

- Easy maintenance, as the design allows service or replacement of the insert without removing the valve housing from the installation.

- Uncomplicated waste handling – at end of use, valve housing and insert are easy to separate and sort properly.

FlowCon’s range of DPCVs includes:

DPCV working principle

What is a DPCV?

A DPCV is a valve that operates to maintain a constant differential pressure between two points independent of supplied pump head.

The DPCV is installed in the return pipe and used in conjunction with a partner valve in the supply pipe. The partner valve can be a simple T-connection, an isolating ball valve, a static balancing valve or a dynamic balancing valve – FlowCon offers the three later partner valve options.

Why choose a DPCV?

With a DPCV installed in Your cooling system, You will achieve reduced energy consumption, avoid the risk of annoying noise and have a simple commissioning process. FlowCon’s DPCV inserts are the energy efficient choice due to a minimum differential pressure of only 3 kPaD to activate the valve.

How does a DPCV work?

A DPCV includes a diaphragm, a spring and a capillary tube connecting the partner valve in the supply pipe and the DPCV valve in the return pipe to control the circuit pressure loss.

• ΔP Control

The DPCV diaphragm will regulate to control ΔpC (differential pressure across the circuit) depending on pressure impulse from the supply side and direct pressure from the return side. The spring force will equal the ΔpC.

In all FlowCon DPCVs the diaphragm will be a rolling diaphragm which will result in a very compact valve design. Depending on the FlowCon Differential Pressure Control Valve selected, ΔpC may be fixed or externally adjustable.

Questions?

Then Give Us a Call

If You have any questions, either in regard to FlowCon's products and services or how and where to use FlowCon products, just get in touch and we will be pleased to assist.

We will react as soon as possible, and written reply is normally within 8 hours if Your question is asked in English and during office hours. Other languages and requests asked during vacation time or weekends may experience longer response time. Likewise, for any special – out of standard – requests, You may not see an immediate reply, but we are responsive.

#YourEnvironmentOurCommitment

Some FlowCon DPCV Projects

See all projects

New massive T4 at Urumqi International Airport, China

Precise control, easy commissioning, scalability, efficiency, and lower operating costs is why FlowCon was selected

New Terminal at Hangzhou Xiaoshan International Airport, China

Huge project providing double terminal area to handle triple number of air travelers

PRIME PARK in City of Moscow

9 towers for mixed use and high-end residential accommodation – new tower is also supplied with FlowCon valves

JTC Poultry Processing Hub, Singapore

Singapore's First Poultry Processing Hub - super smart building to handle everything from purchasing live chicken, over the slaughter process to meat…

Axel Towers, Copenhagen, Denmark

Including both FlowCon Balancing Valves and DPCVs on heating and cooling