Dynamic Balancing Valves

What is Dynamic Balancing or Automatic Balancing?

Dynamic Balancing or Automatic Balancing Valves – also commonly known as ABVs – are two words for the same thing. Dynamic balancing valves ensure that the design flow will not be exceeded regardless of pressure fluctuations in the system. These valves can be used in basically any construction-based heating or cooling system.

Dynamic balancing is – contrary to static balancing – a completely pressure independent solution. This secures a HVAC system free from overflow or starvation even at partial loads. Consequently, equipment will maintain their efficiency, correct temperature is transferred, and the right indoor temperature is secured at lowest possible energy consumption. Another benefit when using automatic balancing is no piping restrictions (no added length of straight pipe before and after the valve), reduced installation time and practically no commissioning time.

They are an easy solution to consultants, mechanical- and electrical contractors and end-users - due to the flexible solution, wide range of flow rates, nil commissioning and low minimum ΔP.

FlowCon’s range of Dynamic/Automatic Balancing Valves includes:

#YourEnvironmentOurCommitment

Why choose Dynamic/Automatic Balancing Valve (ABV)?

An ABV will ensure that design flow (100% flow) will not be exceeded regardless of system pressure changes. And they are the right choice for new constructions as well as refurbishment projects.

How does a Dynamic/Automatic Balancing Valve (ABV) work?

FlowCon offers two solutions of insert-based dynamic balancing:

• E-JUST Insert

The balancing function of the E-JUST is based on the ‘rolling diaphragm’ technology, which has been on the marked for more than 25 years and is durable and well-tested. Any E-JUST is stepless adjustable to 41 unique settings and may be adjusted without isolating the valve or removed the insert from the system.

The rolling diaphragm will maintain a constant ΔP across the outlet resulting in the specified flow based on inlet setting.

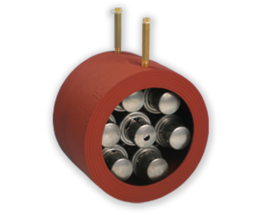

• Stainless Steel Insert

The balancing function of the Stainless Steel insert is based on the ‘moving cup’ technology. This technology is documented and well-proven with more than 50 years on the market. A Stainless Steel insert is factory pre-set to a unique flow rate, and the range covers a wide selection of flows.

The moving cup operates on pressure and the effective open orifice area of the insert is automatically adjusted to the point where the specified flow rate will be delivered.

In addition, FlowCon offers two solutions of built-in dynamic balancing:

• SH Valve

The balancing function of the SH is – like E-JUST – based on the ‘rolling diaphragm’ technology, which has been on the marked for more than 25 years and is durable and well-tested. Any SH is stepless adjustable to 51 unique settings and may be adjusted without isolating the valve or removed the valve from the system.

The rolling diaphragm will maintain a constant ΔP across the outlet resulting in the specified flow based on inlet setting.

• Pure Valve

The balancing function of the Pure is – like the stainless steel insert – based on the ‘moving cup’ technology. This technology is documented and well-proven with more than 50 years on the market. A Pure is factory pre-set to a unique flow rate, and the range covers a wide selection of flows.

The moving cup operates on pressure and the effective open orifice area of the adjustment unit is automatically adjusted to the point where the specified flow rate will be delivered.

Questions?

Then Give Us a Call

If You have any questions, either in regard to FlowCon's products and services or how and where to use FlowCon products, just get in touch and we will be pleased to assist.

We will react as soon as possible, and written reply is normally within 8 hours if Your question is asked in English and during office hours. Other languages and requests asked during vacation time or weekends may experience longer response time. Likewise, for any special – out of standard – requests, You may not see an immediate reply, but we are responsive.

Some FlowCon Dynamic/Automatic Balancing Projects

See all projects

New Tobolsk Airport in Siberia, Russia

To obtain better temperature control in the terminal building and associated buildings, FlowCon DPCV and dynamic balancing valves are installed…

PRIME PARK in City of Moscow

9 towers for mixed use and high-end residential accommodation – new tower is also supplied with FlowCon valves

Mercedes-Benz HQ in Nieuwegein, The Netherlands

Circular Building - going from old and empty to modern and sustainable

"The Catalyst" Newcastle University, UK

New building at Newcastle Helix campus, UK, rated BREEAM Outstanding includes FlowCon By-Pass Mini assemblies with PICVs or ABVs.