Importance of Control Curves in PICVs

By Christina Cohr, CCO, M.Eng (Export) and Torben Ibsen, President, M.Sc (Mech.Eng), FlowCon International ApS, Denmark - updated 05.2024

A pressure Independent Control Valve or PICV, combines 3 functions into one unit, (1) Modulating Control, (2) Dynamic Balancing and (3) Differential Pressure Control.

Control Curve Theory

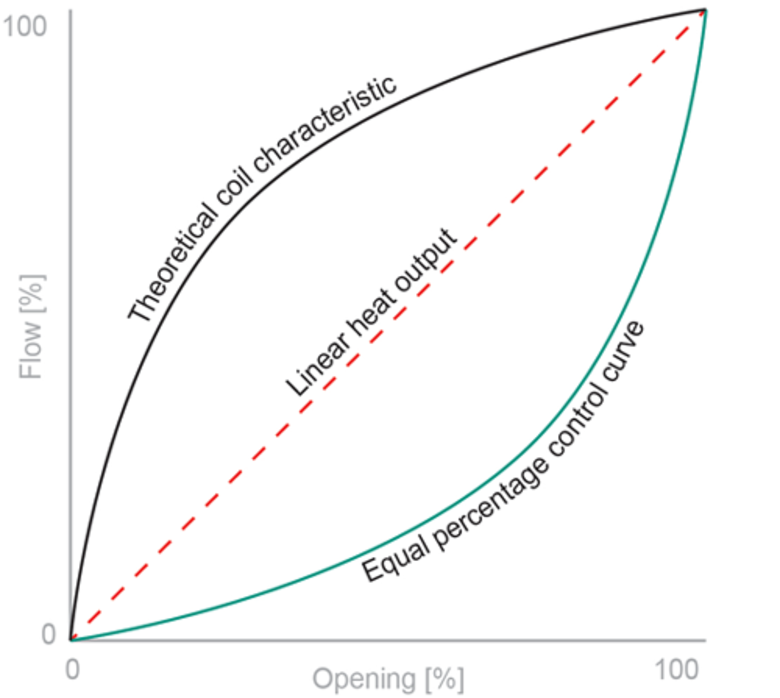

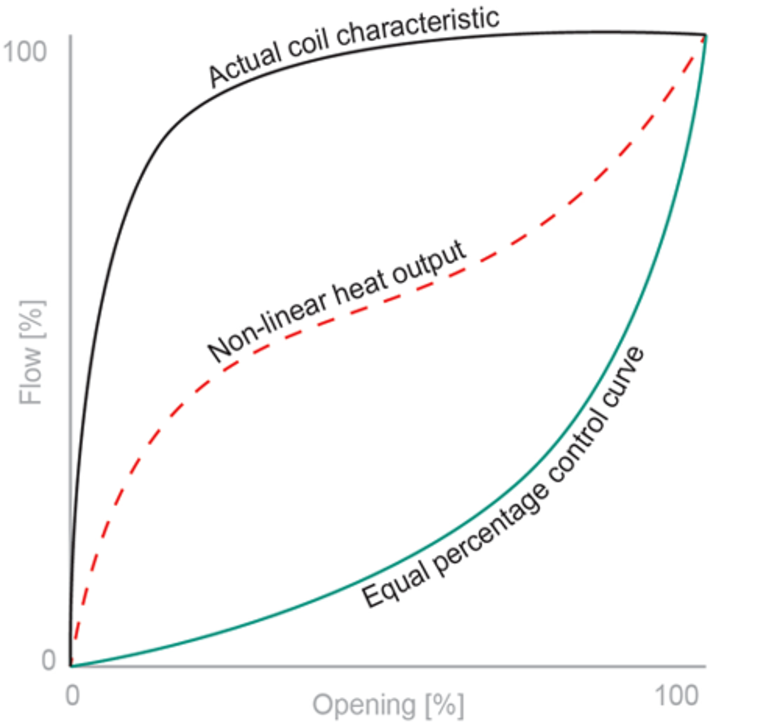

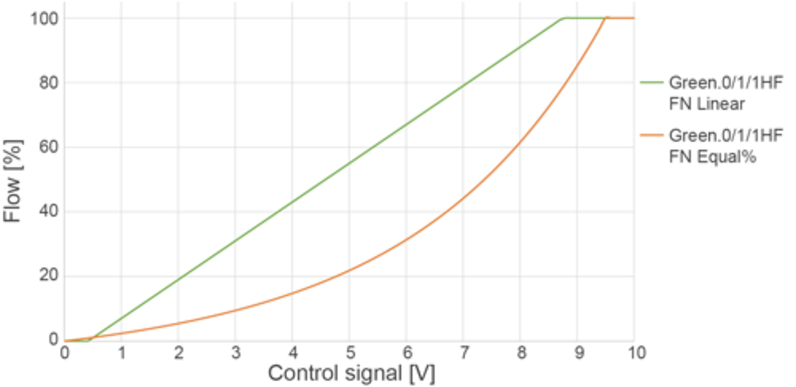

According to ASHRAE’s “Fundamentals of HVAC control”, The desired heat transfer output of a coil should be linear. The heat transfer output is provided as the correlation between the coil characteristic and control valve characteristic. ASHRAE provides a theoretical terminal characteristic, equivalent to a square root curve, meaning that a linear heat output will require an identical curve, except with its structure reversed, as provided by an equal percentage control valve.

Please note that the coil performance curve provided by ASHRAE should be considered more a theoretical representation or symbol, rather than an actual curve. By examining the coil curves published in the manufacturers' literature it can be seen that the actual coil performance is not a mirroring of an equal percentage control curve and a PICV equal% control will therefore not per definition provide the preferred linear heat transfer.

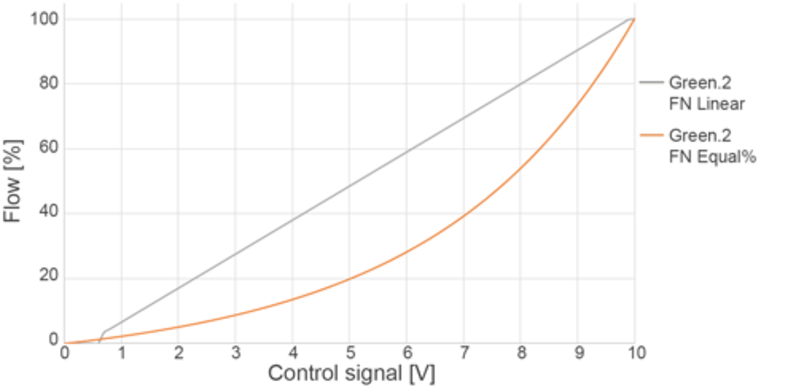

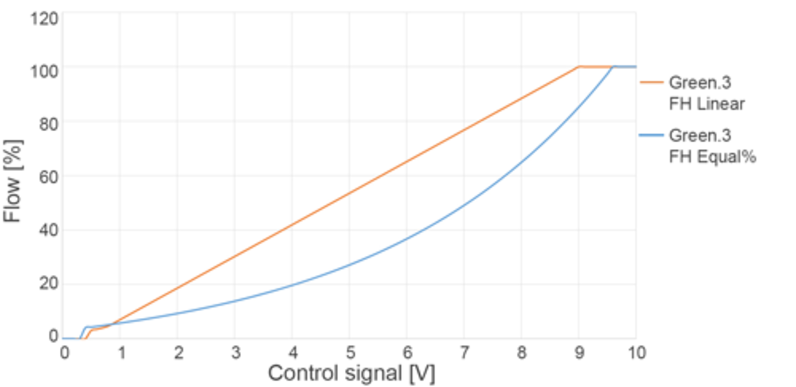

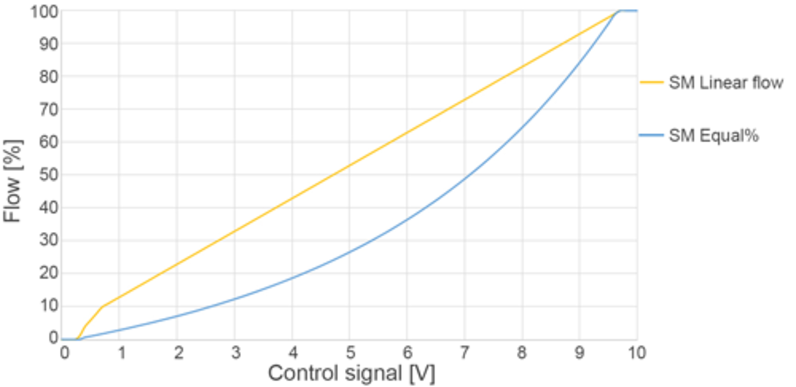

As a rule of thumb, equal percentage control valves are significantly more accurate in low load situations i.e. 0-50% of rated valve capacity or predominantly used in the 0-5V DC control range, whereas linear valves are generally preferred for higher loads and control ranges.

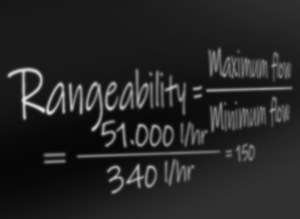

When discussing heat transfer output and control curves, it is - besides choosing the applicable characteristic to secure optimum heat output control - very important to discuss accuracy, turn down ratioand repeatability.

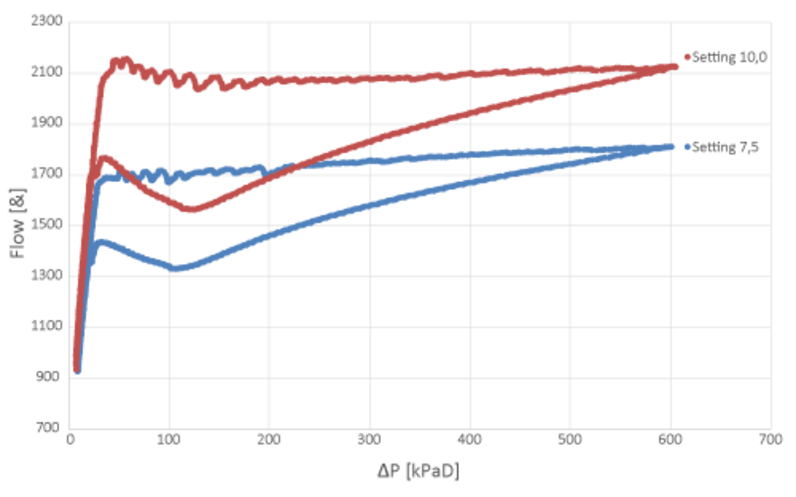

- Accuracy identifies the tolerance between the manufacturer-provided flow values, control curves and the actual values provided. The accuracy generally covers the mechanical tolerance – i.e. variations between different production series - and the pressure accuracy over pressure fluctuations.

- Turn down ratio identifies the lowest flow rate the valve can control to and can be used to identify the “opening jump” of a valve. Equal percentage controls generally provide smaller “opening jumps” than linear valves, as they open slower.

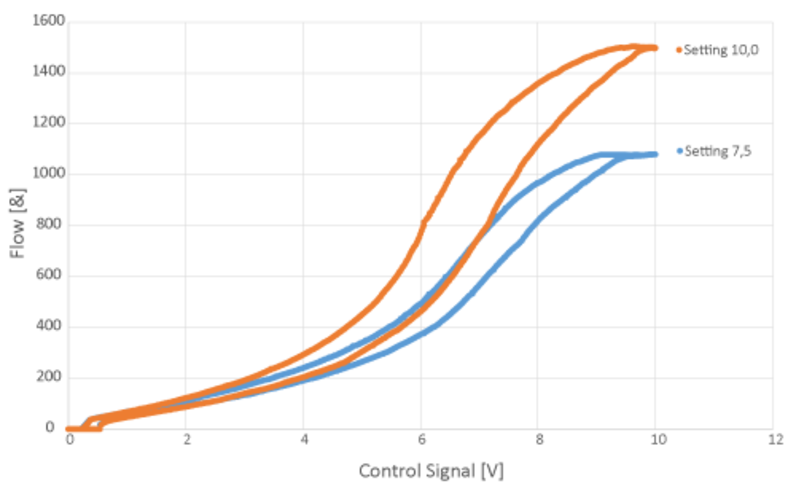

- Repeatability identifies the tolerance seen in the same valve due to hysteresis, pressure fluctuations etc. Valves with poor repeatability will essentially be capable of offering different flow output at the same control signals, meaning that a control curve discussion becomes less relevant, as it becomes avariable.

Read more

In other words, poor flow control provides inconsistent control curves, regardless of the control curve characteristics. Please see below curves illustrating each of the above points.

FlowCon PICV Solutions

The FlowCon range of PICVs includes FlowCon Essentia, FlowCon Green, FlowCon GreEQ and FlowCon SM, which cover sizes from DN15-250. Key characteristics for all the FlowCon PICVs are a wide range of max. flow settings, external flow adjust-ability, 100% authority, automatic balancing and pressure independency. Furthermore, an important detail involving the entire range is the fact that actuator and valve are developed as a pair and not as two individual components, allowing focus purely on the flow output of the PICV (combination of actuator and valve). This results in best curves and accuracies seen in the market.

Pressure Independency

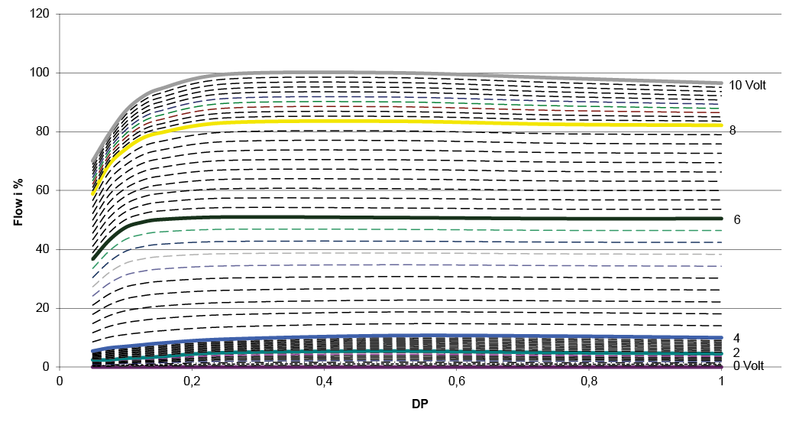

Operating pressure and flow range would vary as per valve type and size, but pressure independency will be achieved as illustrated below regardless of valve choice or the valve’s chosen max. flow pre-setting.

The best-in-class accuracy and repeatability combined with extremely low “opening jumps” result in very stable, predictable and repeatable control curves, regardless of pressure variations. The flow output will always be consistent at identical control signals.

Linear Stroke

Both the FlowCon Essentia and the FlowCon Green/GreEQ include full spindle stoke length, independent of max. flow setting and will work with a linear stoke movement controlled by the actuator.

FlowCon Essentia is a small size valve, normally seen as a low-cost model for chilled beams with ON/OFF control whereas the FlowCon Green/GreEQ will have a wider application range and simultaneously having a serviceable regulation element. Actuators for these valves have the feature of either linear or equal percentage control characteristic and performance charts are identical and repeatable for all selectable pre-settings. As the GreEQ valve is equal% in design it works better with linear control actuators. This again is an exclusive feature for the FlowCon PICVs given that valves and actuators are developed jointly with 100% focus on the water output characteristics.

(Linear and Equal% Control Mode)

(Linear and Equal% Control Mode)

(Linear and Equal% Control Mode)

Rotary Stroke

FlowCon SM is in many ways state-of-the-art PICV. This valve series is in fact the world's first PICV introduced more than 25 years ago. The SM today includes a modern 2160° (up to DN150) / 3600° (DN200/250) rotating actuator providing an intuitive and user-friendly solution with large display and touch buttons for easy actuator programming and valve setting. Alternatively, the actuator is available in a BACnet solution allowing remote BMS-programming and monitoring. The SM valve and actuator are naturally – similarly to the Green range – developed as a pair for optimal performance.

No matter which valve size (DN15-250) the same smart SM-actuator, providing identical control curves, is used making it a simple choice.

(Linear and Equal% Control Mode)

Conclusion

When choosing FlowCon PICVs the best performance charts will be ensured. Control curves are identical for all pre-settings for each valve type and pressure independency curves are exclusive in the market, when looking at accuracy and repeatability resulting in reliable operations and stable indoor conditions.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs