PICV Rangeability, Turndown Ratio and Actuator Resolution

By Dacian Roman, Ph.D. Mechanical Engineering, FlowCon International ApS, Denmark - Updated 07.2025

PICVs (Pressure Independent Control Valves) are specialized hydronic valves that integrate flow regulation and flow control including pressure compensation functions, providing stable flow across varying pressure conditions in HVAC systems. For proper specification, evaluation, and performance assessment, three technical concepts are essential: Rangeability, Turndown Ratio and Actuator Resolution.

Rangeability

The term Inherent Rangeability is defined as the ratio of the largest flow coefficient (Φmax) to the smallest flow coefficient (Φmin) within which the deviation from the stated inherent flow characteristic does not exceed the allowable deviation (IEC 60534-2-4:2009). This means that rangeability is determined by the maximum and minimum flow coefficients, only on the portion of the operating range that remains within specified tolerance limits.

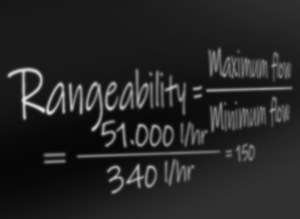

More practically, the rangeability value is given by the relationship of the maximum flow to the minimum flow based on laboratorytesting of the valve body alone (2024 ASHRAE Handbook - HVAC Systems and Equipment).

This definition of rangeability pertains to the results obtained from testing the valve body alone under controlled, optimal laboratory conditions (at maximum valve opening and maximum rated differential pressure), and it indicates the valve's ability to regulate the smallest fraction of its maximum flow.

The methodology for calculating rangeability is directly applicable to conventional pressure-dependent control valves, as both the maximum and minimum controllable flow rates, used in the numerator and denominator of the rangeability expression, can be determined solely based on the valve body characteristics. In contrast, for PICVs, while the maximum controllable flow is readily identifiable, the determination of the minimum controllable flow inherently requires the presence of an actuator. This is due to the PICV’s capability to modulate flow rates down to fractions of its minimum settable value, a level of precision achievable only through actuator-driven control.

In all applications, the control valves and especially the PICVs are used together with an actuator to maintain the desired flow rates. The actuator's responsiveness and resolution are crucial for optimal control. Therefore, understanding the combined performance of the valve and actuator is essential for accurate flow control in real-world scenarios.

With these considerations in mind, FlowCon determines a theoretical minimum controllable flow for rangeability values in the presence of a FlowCon actuator (see table 1 below in “read more”).

Read more

Turndown Ratio

In contrast with the rangeability, the classic definition of Turndown Ratio is directly applicable to PICVs as turndown is the ratio of the valve assembly’s (valve + actuator + linkage) maximum usable flow to the minimum controllable flow installed in a system (2024 ASHRAE Handbook - HVAC Systems and Equipment).

The turndown ratio reflects the valve’s operational effectiveness under real-world conditions. In engineering practice, the maximum flow rate - previously identified during the rangeability assessment - is a critical factor in valve selection. To ensure precise control, valves are typically sized to function within 20% to 80% of their nominal flow capacity. Consequently, the maximum usable flow value, which serves as the numerator in the turndown ratio calculation, corresponds directly to this selected design flow.

Turndown ratio offers a realistic measure of the valve's performance in actual operating conditions. It accounts for the actuator's influence, providing a more accurate representation of the system's control capabilities. Turndown ratio depends not just on the valve mechanics but also on actuator resolution and type (e.g. modulating, 2-position or 3-point floating), stroke limitation (if any), system conditions, etc.

FlowCon notes that their PICVs with separate flow rate setting and control features, i.e. Essentia.1/2, Green and GreEQ PICVs - maintain full actuator stroke regardless of flow setting, enabling consistent turndown ratio of 100:1 or more independent of flow setting. The exceptions are Essentia.0 and FIT-G. Essentia.0 has a reduced stroke at lower settings and therefore the turndown ratio equals the lower rangeability of 15:1. As for FIT-G turndown ratio will be 100:1 but limited to 80:1 by the actuator resolution due to the required 2-10V control signal.

For the FlowCon PICVs with common flow rate setting and control features, like FlowCon SM and FIT, which work with a multi-rotational actuator of high resolution, turndown ratio will still be >100:1, even though stroke rotation is reduced for lower adjust-ments, because the rotation will never be less than 360° for any flow setting (see table 1 on page 4).

In conclusion, the turndown ratio of a PICV is an important parameter that provides a practical indication of how well the valve can modulate flow. A higher turndown ratio indicates better control over a wide range of flow rates, improving system stability and efficiency. Efficient flow control reduces energy consumption, contributing to cost savings and improved CO2 footprint.

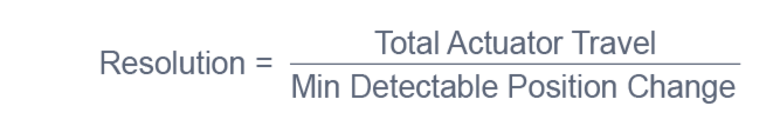

Resolution

Actuator resolution (provided by the actuator suppliers) defines how finely a valve can be modulated based on the actuator's control input.

The resolution defines how accurately the valve can be controlled by the actuator. The integration of high-resolution actuators can make or break the valve's ability to manage the PICV’s flow rates. A high-resolution actuator contributes to improved system efficiency and reliability, enabling finer control over lower flow rates, and enhancing the overall turndown ratio.

The FlowCon 0-10V actuators hold a resolution of 100:1 for FN / FNP, FH, FNJ and FNR actuators used for FlowCon Essentia, FlowCon Green and FlowCon GreEQ ranges and FN and FH actuators for FlowCon FIT-G will be 80:1 as this works 2-10V. Resolution is 1000:1 for SM actuators used for FlowCon SM range when using a 0-10V signal and 800:1 for FlowCon FIT, which works with a 2-10V signal (see table 1).

A PICV assembly (valve and actuator) is limited by the turn-down ratio and actuator resolution, to the lower of the two factors. For example, if a valve has a turndown ratio of 300:1, but the actuator resolution is 50:1, the overall turndown ratio of this combination will be downgraded to 50:1. This example under-scores the critical importance of selecting an appropriate actuator to meet the specific requirements of the selected valve within the system.

Looking for more Information?

Contact FlowCon to benefit from our extensive expertise in PICV technology. We're here to provide further guidance and help you select the optimal PICV solution for your application. All our PICVs are third-party tested in accordance with the BSRIA BTS 01 standard, covering Pressure Independency, Accuracy, Repeatability, Control Characteristics, and Seat Leakage.

Calculation Examples

To help with the understanding of the terms presented above, please consider the following two FlowCon PICV examples. It must be emphasized that the parameters involved in calculations are dependent on the local testing conditions such as fluid characteristics (water only or a glycol mixture), temperature, pressure, and the type of pump and actuator used. Both examples are based on measurements taken in water at 21°C, and at 4 bar static pressure.

FlowCon Green.1HF

Rangeability

The max. controllable flow is equal to the highest settable max. flow (setting 5.0) = 2650 l/hr and the minimum controllable flow is 26 l/hr. This will result in a rangeability of 100:1.

Turndown Ratio

The value of the max. usable flow will in this example be given at the highest settable max. flow (setting 5.0) = 2650 l/hr and at the lowest settable max. flow (setting 1.5) = 620 l/hr. However, because this type of PICVs has a separate flow rate setting and control features, and maintains full stroke regardless of the flow setting, the turndown ratio at both setting 5.0 and setting 1.5 will be 100:1.

Resolution

The standard actuator for the FlowCon Green.1HF is the FlowCon FN and commonly the control signal is 0-10V modulating. This will provide an actuator resolution of 100:1.

FlowCon SM.4.1

Rangeability

The max. controllable flow is equal to the highest settable max. flow = 33800 l/hr and the minimum controllable flow is 34 l/hr. This will result in a rangeability of 1000:1.

Turndown Ratio

The value of the max. usable flow will in this example be given at the highest settable max. flow = 33800 l/hr and at the lowest settable max. flow = 12600 l/hr. The minimum controllable flow for both is 34 l/hr. Because this type of valve has a common flow rate setting and control features, the stroke of the actuator is reduced. This will result in a turndown ratio at highest max. flow of 994:1 and at lowest max. flow of 360:1.

Resolution

The standard actuator for the FlowCon SM.4.1 is the FlowCon SM and commonly the control signal is 0-10V modulating. This will provide an actuator resolution of 1000:1.

Table 1: Overview of Rangeability, Turndown Ratio, control Range and Resolution

FlowCon Essentia

| Model |

Lowest Settable Max. Flow |

Highest Settable Max. Flow |

Minimum Controlled Flow |

Rangeability |

Turndown Ratio (at highest settable max. flow) |

Resolution 0(2)-10V |

| [l/hr] | [l/hr] | [l/hr] | [x:1] | [x:1] | [x:1] | |

| FlowCon Essentia.0 | 35 | 465 | 31 | 15 | 15 | 100 |

| FlowCon Essentia.1 | 105 | 1.000 | 10 | 100 | 100 | 100 |

| FlowCon Essentia.2 | 150 | 1.700 | 17 | 100 | 100 | 100 |

FlowCon Green

| Model |

Lowest Settable Max. Flow |

Highest Settable Max. Flow |

Minimum Controlled Flow |

Rangeability |

Turndown Ratio (at highest settable max. flow) |

Resolution 0(2)-10V |

| [l/hr] | [l/hr] | [l/hr] | [x:1] | [x:1] | [x:1] | |

| FlowCon Green.0 | 37 | 575 | 5,7 | 100 | 100 | 100 |

| FlowCon Green.1 | 64 | 1.110 | 11 | 100 | 100 | 100 |

| FlowCon Green.1HF | 620 | 2.650 | 26 | 100 | 100 | 100 |

| FlowCon Green.2 | 865 | 4.630 | 46 | 100 | 100 | 100 |

| FlowCon Green.3 | 1.900 | 13.647 | 136 | 100 | 100 | 100 |

FlowCon GreEQ

| Model |

Lowest Settable Max. Flow |

Highest Settable Max. Flow |

Minimum Controlled Flow |

Rangeability |

Turndown Ratio (at highest settable max. flow) |

Resolution 0(2)-10V |

| [l/hr] | [l/hr] | [l/hr] | [x:1] | [x:1] | [x:1] | |

| FlowCon GreEQ.0 | 17 | 454 | 4,5 | 100 | 100 | 100 |

| FlowCon GreEQ.1 | 27 | 805 | 8 | 100 | 100 | 100 |

| FlowCon GreEQ.2 | 850 | 2.160 | 21 | 100 | 100 | 100 |

FlowCon SM

| Model |

Lowest Settable Max. Flow |

Highest Settable Max. Flow |

Minimum Controlled Flow |

Rangeability |

Turndown Ratio (at highest settable max. flow) |

Resolution 0(2)-10V |

| [l/hr] | [l/hr] | [l/hr] | [x:1] | [x:1] | [x:1] | |

| FlowCon SM.1.1 | 633 | 2.470 | 3 | >100 | >100 | 1000 |

| FlowCon SM.2.1 | 1.850 | 8.420 | 9 | >100 | >100 | 1000 |

| FlowCon SM.3.0 | 5.310 | 15.000 | 15 | >100 | >100 | 1000 |

| FlowCon SM.3.1 | 9.240 | 27.500 | 28 | >100 | >100 | 1000 |

| FlowCon SM.3.2 | 12.800 | 35.600 | 36 | >100 | >100 | 1000 |

| FlowCon SM.4.1 | 12.600 | 33.800 | 34 | >100 | >100 | 1000 |

| FlowCon SM.4.2 | 17.000 | 51.000 | 51 | >100 | >100 | 1000 |

| FlowCon SM.4.3 | 13.300 | 72.700 | 73 | >100 | >100 | 1000 |

| FlowCon SM.5.1 | 23.300 | 83.800 | 84 | >100 | >100 | 1000 |

| FlowCon SM.5.2 | 25.600 | 106.000 | 106 | >100 | >100 | 1000 |

| FlowCon SM.6.2 | 33.100 | 277.000 | 277 | >100 | >100 | 1000 |

FlowCon FIT

| Model |

Lowest Settable Max. Flow |

Highest Settable Max. Flow |

Minimum Controlled Flow |

Rangeability |

Turndown Ratio (at highest settable max. flow) |

Resolution 0(2)-10V |

| [l/hr] | [l/hr] | [l/hr] | [x:1] | [x:1] | [x:1] | |

| FlowCon FIT-G.0 | 37 | 575 | 5,7 | 100 | 100 | 80 |

| FlowCon FIT-G.1 | 64 | 1110 | 11 | 100 | 100 | 80 |

| FlowCon FIT-G.2 | 865 | 4630 | 46 | 100 | 100 | 80 |

| FlowCon FIT-G.3 | 1900 | 13647 | 136 | 100 | 100 | 80 |

| FlowCon FIT.1.1 | 633 | 2470 | 3 | >100 | >100 | 800 |

| FlowCon FIT.2.1 | 1850 | 8420 | 9 | >100 | >100 | 800 |

| FlowCon FIT.3.0 | 5310 | 15000 | 15 | >100 | >100 | 800 |

| FlowCon FIT.3.1 | 9240 | 27500 | 28 | >100 | >100 | 800 |

| FlowCon FIT.3.2 | 12800 | 35600 | 36 | >100 | >100 | 800 |

| FlowCon FIT.4.1 | 12600 | 33800 | 34 | >100 | >100 | 800 |

| FlowCon FIT.4.2 | 17000 | 51000 | 51 | >100 | >100 | 800 |

| FlowCon FIT.4.3 | 13300 | 72700 | 73 | >100 | >100 | 800 |

| FlowCon FIT.5.1 | 23300 | 83800 | 84 | >100 | >100 | 800 |

| FlowCon FIT.5.2 | 25600 | 106000 | 106 | >100 | >100 | 800 |

| FlowCon FIT.6.2 | 33100 | 277000 | 277 | >100 | >100 | 800 |

Source: FlowCon Data

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

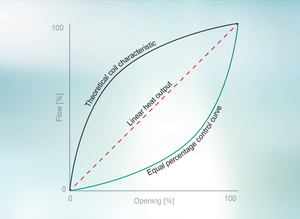

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs