FlowCon Valves - IEC60534-4 Leakage Classification

By Gitte Pedersen, R&D Manager, B.Eng (Integrated Design), FlowCon International ApS, Denmark - Updated 05.2024

FlowCon International complies with the International Standard IEC60534-4 regarding leakage specification. The data used is taken from the International standard IEC60534-4. Sections of the standard are high-lighted in this document, making it possible to calculate the maximum leakage according to the standard

1. General

Specified leakage test is carried out 100% on each insert/valve.

2. Test Medium

Test medium shall be liquid and at a temperature of 20°C.

3. Water

Test medium shall be clean water and with maximum 50% glycol.

4. Air Pockets

Care shall be taken to eliminate air pockets inside the valve housing and piping.

5. Test Pressure

Hydrostatic shell test pressure shall be according to the design code or standard for the valve housing or, alternatively, it shall be no less than 1.2 x the 20°C rated pressure, whichever is appropriate.

6. Test Actuator

The actuator shall be adjusted to meet the operating conditions according to FlowCon’s specifications. The required closing thrust or torque, as a spring or other means, shall then be applied. No allowance or adjustment shall be made to compensate for any difference in seat load obtained when the test differential is less than the maximum valve operating differential pressure.

The test medium shall be applied to the valve housing inlet. The valve housing outlet may be open to the atmosphere or connected to a low head-loss flow measuring device with its outlet open to the atmosphere.

The valve shall be opened, and the valve housing assembly filled completely, including the outlet portion and any downstream connected piping. The valve shall then be closed. When the leakage flow rate has been stabilized, the rate of flow should be observed over a sufficient period to obtain the accuracy specified class IV and V.

The maximum allowable seat leakage as specified for each class shall not exceed the values resulting from the test method as defined.

7. Pressure

The test pressure must be minimum 50% of the maximum operating differential pressure across the valve.

8. Leakage Class

The leakage rate thus obtained can then be compared to the calculated values for classes II, III, IV and V. Classes IV and V are relevant for the included FlowCon valves.

9. Leakage Classification. IEC60534-4

Below table shows maximum allowable seat leakage for each leakage class.

FlowCon defines the rated valve capacity as:

Kv ∗ √max P, where Kv = Qmax : √ΔPmin

| Leakage Class | Test Medium | Test Procedure | Maximum Seat Leakage |

| IV | Liquid | 1 or 2 | 10E-4 * valve capacity (note) |

| V | Liquid | 2 | 1.8 * 10E-5 * ΔP * D |

Note: Rated valve capacity is the flow rate of test fluid that would pass through the valve at rated travel under stated test conditions.

Leakage Classification:

FlowCon Essentia - PICV

Leakage Class IV

FlowCon Essentia.0 (low flow)

Kv = Qmax : √∆Pmin = 0.465 m3/hr : √0.10 bar = 1.47

Maximum seat leakage = Kv * √max P * 10-4 = 1.47 * √6 bar * 10-4 = 0.00036007 m3/hr

Maximum seat leakage = 0.00036007 * 1000 = 0.36 l/hr

FlowCon Essentia.1 (medium flow)

Kv = Qmax : √∆Pmin = 1.000 m3/hr : √0.16 bar = 2.50

Maximum seat leakage = Kv * √max P * 10-4 = 2.50 * √6 bar * 10-4 = 0.000612372 m3/hr

Maximum seat leakage = 0.000612372 * 1000 = 0.61 l/hr

FlowCon Essentia.2 (high flow)

Kv = Qmax : √∆Pmin = 1.700 m3/hr : √0.45 bar = 2.534

Maximum seat leakage = Kv * √max P * 10-4 = 2.534 * √6 bar * 10-4 = 0.000620701 m3/hr

Maximum seat leakage = 0.000620701 * 1000 = 0.62 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin = Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

FlowCon EVS - TCV

Leakage Class V

FlowCon EVS

Maximum seat leakage=1.8 * 10-5 * max P * D

Maximum seat leakage=1.8 * 10-5 * 4 bar * 13.72 mm

Maximum seat leakage = 0.000988 l/hr ~ 0 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin = Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

D = Diameter [mm]

FlowCon FIT - PICV

Leakage Class IV

FlowCon FIT.1.1

Kvs = Qmax : √∆Pmin = 2.47 m3/hr : √0.32 bar = 4.37

Maximum seat leakage = Kvs * √max P * 10-4 = 4.37 * √6 bar * 10-4 = 0.001070427 m3/hr

Maximum seat leakage = 0.001070427 * 1000 = 1.07 l/hr

FlowCon FIT.2.1

Kvs = Qmax : √∆Pmin = 8.42 m3/hr : √0.40 bar = 13.31

Maximum seat leakage = Kvs * √max P * 10-4 = 13.31 * √6 bar * 10-4 = 0.003261052 m3/hr

Maximum seat leakage = 0.003261052 * 1000 = 3.26 l/hr

FlowCon FIT.3.0

Kvs = Qmax : √∆Pmin = 15 m3/hr : √0.30 bar = 27.39

Maximum seat leakage = Kvs * √max P * 10-4 = 27.39 * √8 bar * 10-4 = 0.007747062 m3/hr

Maximum seat leakage = 0.007747062 * 1000 = 7.74 l/hr

FlowCon FIT.3.1

Kvs = Qmax : √∆Pmin = 25.7 m3/hr : √0.30 bar = 46.92

Maximum seat leakage = Kvs * √max P * 10-4 = 46.92 * √8 bar * 10-4 = 0.01327098 m3/hr

Maximum seat leakage = 0.01327098 * 1000 = 13.31 l/hr

FlowCon FIT.3.2

Kvs = Qmax : √∆Pmin = 35.6 m3/hr : √0.35 bar = 60.17

Maximum seat leakage = Kvs * √max P * 10-4 = 60.17 * √8 bar * 10-4 = 0.017018646 m3/hr

Maximum seat leakage = 0.017018646 * 1000 = 17.0 l/hr

FlowCon FIT.4.1

Kvs = Qmax : √∆Pmin = 33.8 m3/hr : √0.30 bar = 61.71

Maximum seat leakage = Kvs * √max P * 10-4 = 61.71 * √8 bar * 10-4 = 0.017454224 m3/hr

Maximum seat leakage = 0.017454224 * 1000 = 17.5 l/hr

FlowCon FIT.4.2

Kvs = Qmax : √∆Pmin = 51 m3/hr : √0.35 bar = 86.20

Maximum seat leakage = Kvs * √max P * 10-4 = 86.20 * √8 bar * 10-4 = 0.024381042 m3/hr

Maximum seat leakage = 0.024381042 * 1000 = 24.4 l/hr

FlowCon FIT.4.3

Kvs = Qmax : √∆Pmin = 72.7 m3/hr : √0.50 bar = 102.81

Maximum seat leakage = Kvs * √max P * 10-4 = 102.81 * √8 bar * 10-4 = 0.029079059 m3/hr

Maximum seat leakage = 0.029079059 * 1000 = 29.1 l/hr

FlowCon FIT.5.1

Kvs = Qmax : √∆Pmin = 83.8 m3/hr : √0.30 bar = 152.99

Maximum seat leakage = Kvs * √max P * 10-4 = 152.99 * √8 bar * 10-4 = 0.043272107 m3/hr

Maximum seat leakage = 0.043272107 * 1000 = 43.27 l/hr

FlowCon FIT.5.2

Kvs = Qmax : √∆Pmin = 106 m3/hr : √0.35 bar = 179.2

Maximum seat leakage = Kvs * √max P * 10-4 = 179.2 * √8 bar * 10-4 = 0.05065713 m3/hr

Maximum seat leakage = 0.05065713 * 1000 = 50.6 l/hr

FlowCon FIT.6.2

Kvs = Qmax : √∆Pmin = 277 m3/hr : √0.35 bar = 468.22

Maximum seat leakage = Kvs * √max P * 10-4 = 468.22 * √8 bar * 10-4 = 0.132432615 m3/hr

Maximum seat leakage = 0.132432615 * 1000 = 132 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin = Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

FlowCon FIT-G - PICV

Leakage Class IV

FlowCon FIT-G.0

Kvs = Qmax : √∆Pmin = 0.575 m3/hr : √0.16 bar = 1.4375

Maximum seat leakage = Kvs * √max P * 10-4 = 1.4375 * √8 bar * 10-4 = 0.000406586 m3/hr

Maximum seat leakage = 0.000406586 * 1000 = 0.407 l/hr

FlowCon FIT-G.1

Kvs = Qmax : √∆Pmin = 1.11 m3/hr : √0.30 bar = 2.0266

Maximum seat leakage = Kvs * √max P * 10-4 = 2.0266 * √8 bar * 10-4 = 0.000573209 m3/hr

Maximum seat leakage = 0.000573209 * 1000 = 0.573 l/hr

FlowCon FIT-G.2

Kvs = Qmax : √∆Pmin = 4.630 m3/hr : √0.16 bar = 11.575

Maximum seat leakage = Kvs * √max P * 10-4 = 11.575 * √8 bar * 10-4 = 0.003273904 m3/hr

Maximum seat leakage = 0.003273904 * 1000 = 3.27 l/hr

FlowCon FIT-G.3

Kvs = Qmax : √∆Pmin = 13.647 m3/hr : √0.16 bar = 34.12

Maximum seat leakage = Kvs * √max P * 10-4 = 34.12 * √8 bar * 10-4 = 0.00965 m3/hr

Maximum seat leakage = 0.00965 * 1000 = 9.65 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin = Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

FlowCon Green - PICV

Leakage Class IV

FlowCon Green.0

Kvs = Qmax : √∆Pmin = 0.575 m3/hr : √0.16 bar = 1.4375

Maximum seat leakage = Kvs * √max P * 10-4 = 1.4375 * √8 bar * 10-4 = 0.000406586 m3/hr

Maximum seat leakage = 0.000406586 * 1000 = 0.407 l/hr

FlowCon Green.1

Kvs = Qmax : √∆Pmin = 1.11 m3/hr : √0.30 bar = 2.0266

Maximum seat leakage = Kvs * √max P * 10-4 = 2.0266 * √8 bar * 10-4 = 0.000573209 m3/hr

Maximum seat leakage = 0.000573209 * 1000 = 0.573 l/hr

FlowCon Green.1HF

Kvs = Qmax : √∆Pmin = 2.65 m3/hr : √0.35 bar = 4.4797

Maximum seat leakage = Kvs * √max P * 10-4 = 4.797 * √8 bar * 10-4 = 0.00126677 m3/hr

Maximum seat leakage = 0.00126677 * 1000 = 1.27 l/hr

FlowCon Green.2

Kvs = Qmax : √∆Pmin = 4.630 m3/hr : √0.16 bar = 11.575

Maximum seat leakage = Kvs * √max P * 10-4 = 11.575 * √8 bar * 10-4 = 0.003273904 m3/hr

Maximum seat leakage = 0.003273904 * 1000 = 3.27 l/hr

FlowCon Green.3

Kvs = Qmax : √∆Pmin = 13.647 m3/hr : √0.16 bar = 34.12

Maximum seat leakage = Kvs * √max P * 10-4 = 34.12 * √8 bar * 10-4 = 0.00965 m3/hr

Maximum seat leakage = 0.00965 * 1000 = 9.65 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin= Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

FlowCon GreEQ - PICV

Leakage Class IV

FlowCon GreEQ.0

Kvs = Qmax : √∆Pmin = 0.454 m3/hr : √0.16 bar = 1.135

Maximum seat leakage = Kvs * √max P * 10-4 = 1.135 * √6 bar * 10-4 = 0.000278 m3/hr

Maximum seat leakage = 0.000278 * 1000 = 0.278 l/hr

FlowCon GreEQ.1

Kvs = Qmax : √∆Pmin = 0.805 m3/hr : √0.30 bar = 1.4697

Maximum seat leakage = Kvs * √max P * 10-4 = 1.4697 * √8 bar * 10-4 = 000416 m3/hr

Maximum seat leakage = 000416 * 1000 = 0.416 l/hr

FlowCon GreEQ.2

Kvs = Qmax : √∆Pmin = 2.16 m3/hr : √0.16 bar = 5.4

Maximum seat leakage = Kvs * √max P * 10-4 = 5.4 * √8 bar * 10-4 = 0.001527 m3/hr

Maximum seat leakage = 0.001527 * 1000 = 1.527 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin = Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

FlowCon SM - PICV

Leakage Class IV

FlowCon SM.1.1

Kvs = Qmax : √∆Pmin = 2.47 m3/hr : √0.32 bar = 4.37

Maximum seat leakage = Kvs * √max P * 10-4 = 4.37 * √6 bar * 10-4 = 0.001070427 m3/hr

Maximum seat leakage = 0.001070427 * 1000 = 1.07 l/hr

FlowCon SM.2.1

Kvs = Qmax : √∆Pmin = 8.42 m3/hr : √0.40 bar = 13.31

Maximum seat leakage = Kvs * √max P * 10-4 = 13.31 * √6 bar * 10-4 = 0.003261052 m3/hr

Maximum seat leakage = 0.003261052 * 1000 = 3.26 l/hr

FlowCon SM.3.0

Kvs = Qmax : √∆Pmin = 15 m3/hr : √0.30 bar = 27.39

Maximum seat leakage = Kvs * √max P * 10-4 = 27.39 * √8 bar * 10-4 = 0.007747062 m3/hr

Maximum seat leakage = 0.007747062 * 1000 = 7.74 l/hr

FlowCon SM.3.1

Kvs = Qmax : √∆Pmin = 25.7 m3/hr : √0.30 bar = 46.92

Maximum seat leakage = Kvs * √max P * 10-4 = 46.92 * √8 bar * 10-4 = 0.01327098 m3/hr

Maximum seat leakage = 0.01327098 * 1000 = 13.31 l/hr

FlowCon SM.3.2

Kvs = Qmax : √∆Pmin = 35.6 m3/hr : √0.35 bar = 60.17

Maximum seat leakage = Kvs * √max P * 10-4 = 60.17 * √8 bar * 10-4 = 0.017018646 m3/hr

Maximum seat leakage = 0.017018646 * 1000 = 17.0 l/hr

FlowCon SM.4.1

Kvs = Qmax : √∆Pmin = 33.8 m3/hr : √0.30 bar = 61.71

Maximum seat leakage = Kvs * √max P * 10-4 = 61.71 * √8 bar * 10-4 = 0.017454224 m3/hr

Maximum seat leakage = 0.017454224 * 1000 = 17.5 l/hr

FlowCon SM.4.2

Kvs = Qmax : √∆Pmin = 51 m3/hr : √0.35 bar = 86.20

Maximum seat leakage = Kvs * √max P * 10-4 = 86.20 * √8 bar * 10-4 = 0.024381042 m3/hr

Maximum seat leakage = 0.024381042 * 1000 = 24.4 l/hr

FlowCon SM.4.3

Kvs = Qmax : √∆Pmin = 72.7 m3/hr : √0.50 bar = 102.81

Maximum seat leakage = Kvs * √max P * 10-4 = 102.81 * √8 bar * 10-4 = 0.029079059 m3/hr

Maximum seat leakage = 0.029079059 * 1000 = 29.1 l/hr

FlowCon SM.5.1

Kvs = Qmax : √∆Pmin = 83.8 m3/hr : √0.30 bar = 152.99

Maximum seat leakage = Kvs * √max P * 10-4 = 152.99 * √8 bar * 10-4 = 0.043272107 m3/hr

Maximum seat leakage = 0.043272107 * 1000 = 43.27 l/hr

FlowCon SM.5.2

Kvs = Qmax : √∆Pmin = 106 m3/hr : √0.35 bar = 179.2

Maximum seat leakage = Kvs * √max P * 10-4 = 179.2 * √8 bar * 10-4 = 0.05065713 m3/hr

Maximum seat leakage = 0.05065713 * 1000 = 50.6 l/hr

FlowCon SM.6.2

Kvs = Qmax : √∆Pmin = 277 m3/hr : √0.35 bar = 468.22

Maximum seat leakage = Kvs * √max P * 10-4 = 468.22 * √8 bar * 10-4 = 0.132432615 m3/hr

Maximum seat leakage = 0.132432615 * 1000 = 132 l/hr

Kv (Kvs) = Qmax : √∆Pmin [m3/hr at 1 bar]

Qmax = Maximum flow rate [m3/hr]

∆Pmin = Minimum operational pressure [bar]

max P = Maximum close off pressure [bar]

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

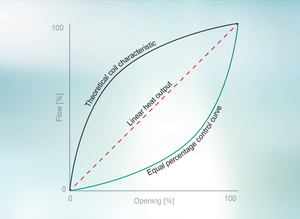

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

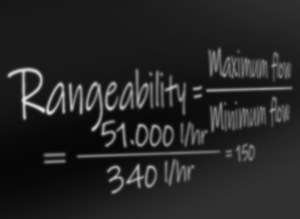

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs