A Word on Valve Authority

By Christina Cohr, CCO, M.Eng (Export), FlowCon International ApS, Denmark with courtesy of FloControl Ltd, United Kingdom - 02.2021

What is Valve Authority?

Valve authority is the definition of how well a modulating control valve will control flow under the influence of other elements in the HVAC system.

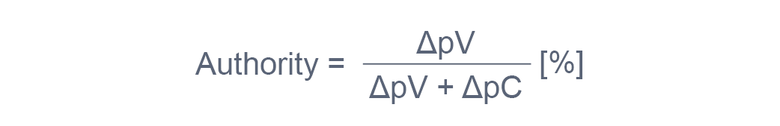

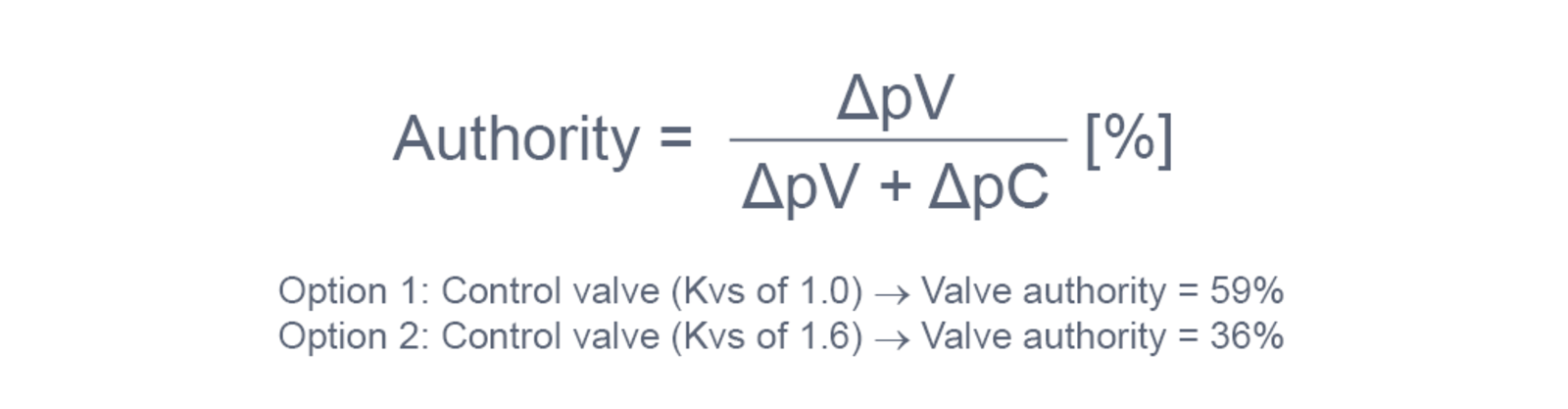

Technically and mathematically valve authority is defined as described next: When the control valve is fully open, the pressure drop (ΔpV) across the control valve is at its minimum. The opposite situation, when the control valve is fully closed, will result in maximum pressure drop across the control valve, which equals ΔpV plus the pressure drop across the remaining circuit (ΔpC), including pipes, fittings, strainer, isolation valve, DPCV and DRV, represented as ΔpV + ΔpC. These pressure drops will define valve authority as the ratio of the pressure drop across the fully open Control Valve (ΔpV) and pressure drop across the rest of the circuit (ΔpC) plus the fully open control valve (ΔpV):

Why is Valve Authority Important?

Authority is used when deciding on control valve size and will help to understand how well the selected control valve is going to perform in the HVAC system. Proper valve sizing will provide high authority and consequently better flow control at any load.

If the control valve is oversized, the pressure drop across the control valve is reduced. For an un-changed maximum differential pressure drop, the authority and the pressure drop across the valve will be low. The valve will need to operate near its closed position to provide any form of acceptable control. In fact, this will result in on/off similar control and room temperature fluctuations and increased wear on the actuator.

On the other hand, if the control valve is under-sized, the pressure drop across the control valve is increased. If maximum differential pressure drop remains unchanged, the authority and the pressure drop across the valve will be high, control will be good, but the energy consumption to transfer the required flow rate through the undersized valve will be high and consequently more costly.

Clearly, a trade off exists between the consideration of control and energy consumption and control valve sizing requires a balance between the two dynamics.

Generally, valve authority is considered divided into 3 groups:

- 0-25% valve authority:

unstable to fair control with low ΔP - 25-50% valve authority:

fair to good control with reasonable ΔP - 50-100% valve authority:

good to excellent control but with high ΔP

For practical purposes control valves are commonly selected to have an authority of 35-75% providing a fair compromise between control and energy consumption.

The Future-Proof Solution

With the emergence of variable speed pumps and Pressure Independent Control Valves, PICVs, authority calculations are almost a thing of the past because a PICV has a valve authority of 100% with a constant minimum differential pressure requirement to make them function. Despite full authority, a PICVs are highly energy efficient. A PICV combines flow control, flow balancing and differential pressure control in one valve solution, eliminating the need for DPCVs and DRVs in the HVAC system.

Read more

Selecting the proper FlowCon PICV is simple. Based on the required design flow rate and available pressure, select the insert, and then select the valve size.

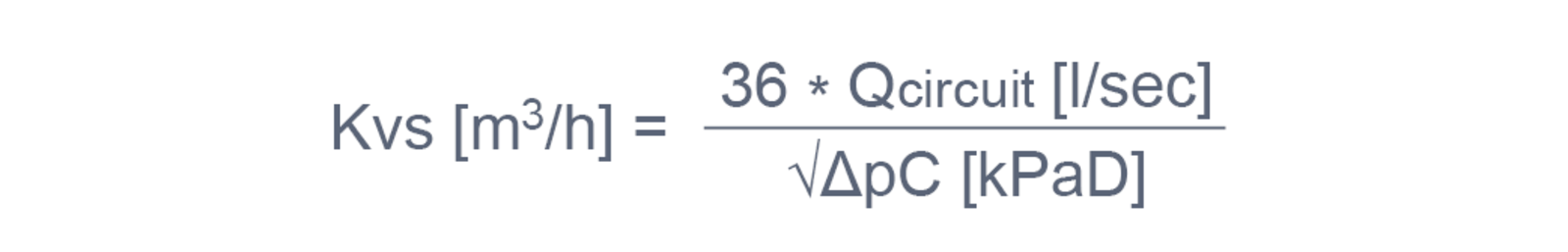

However, in a variable flow system with PICVs, valve authority calculations are still relevant when sizing 3-port and 4-port valves, for e.g. end-of-line control valves to provide terminal unit control and low flow pump protection. To correctly size such valves, circuit flow rate (Qcircuit) and circuit pressure drop (ΔpC) information is required for controlled unit. This will be used to establish the required Kvs value of the control valve to size it correctly. This can be carried out by calculation using the following formula:

Calculation Example

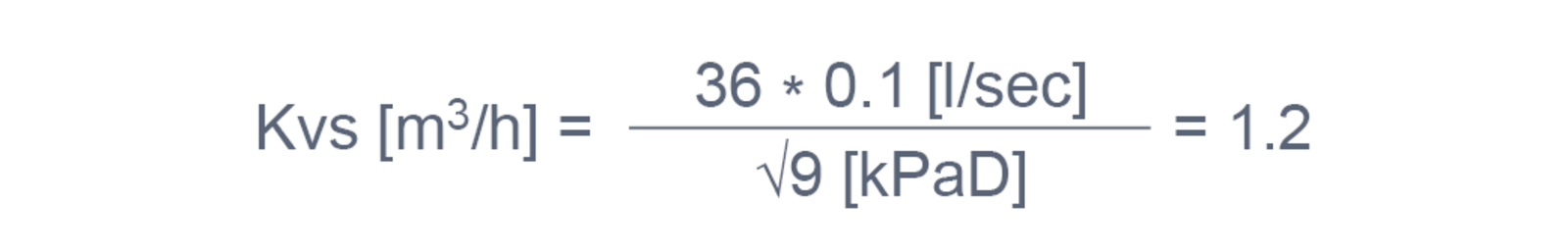

To better understand how to use the control valve authority calculation, let us have a look at a relevant example for a 4-port valve fitted on a FCU with a flow rate (Qcircuit) = 0.1 l/sec and a pressure drop (ΔpC) = 9 kPaD.

By calculation Kvs is:

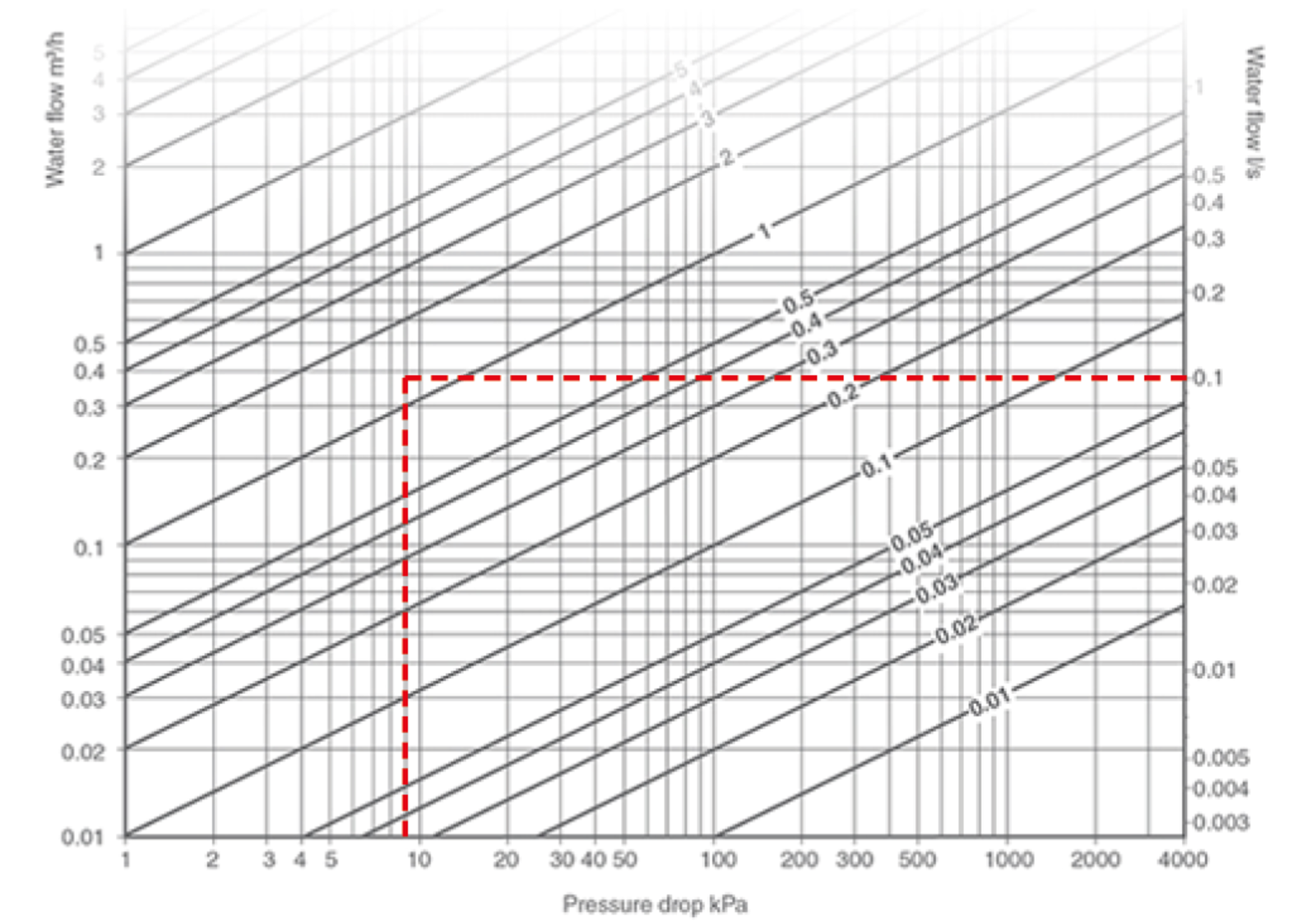

Or by graph look-up, it can be seen that Kvs is 1.2.

However, control valves are only available with Kvs values, which increase in a geometric progression, according to the Reynard series: Kvs: 0.25, 0.63, 1.00, 1.60, 2.5, 4.00, 6.30, 10, 16, …

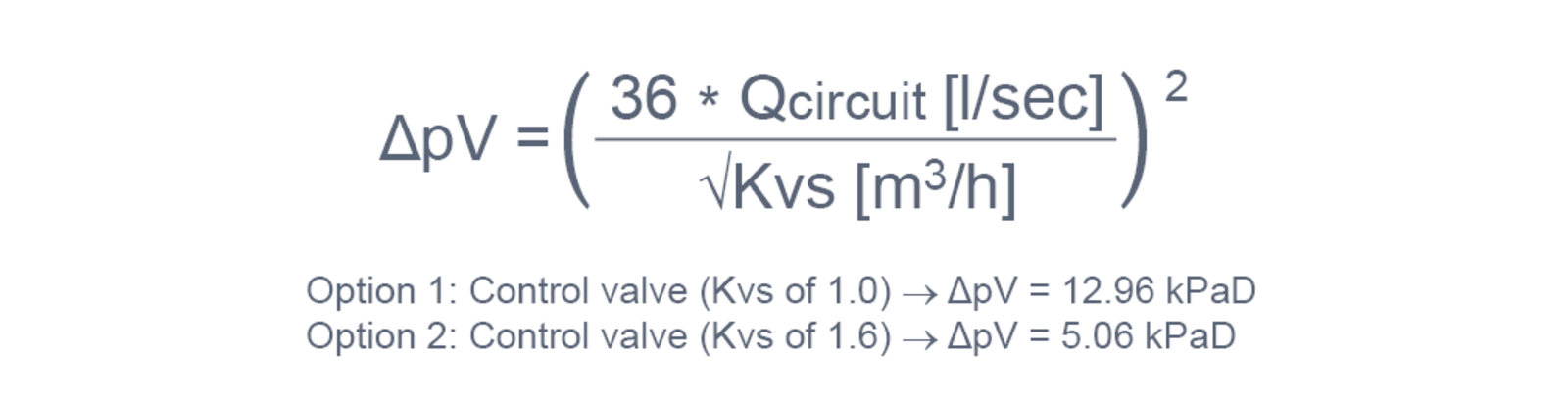

Therefore, the nearest Kvs values will be either 1.00 (Option 1 = undersized control valve) or 1.60 (Option 2 = oversized control valve). To help make the decision we can use the valve authority calculation. First, calculate the (ΔpV) for the two control valve options based on the below formula:

Corresponding Control Valve authority calculation:

In this instance Option 1 would be the better choice of the two because of the ~60% authority being in the good to excellent selection range and the pressure drop of ~13 kPaD is comparable to the circuit/FCU pressure drop.

Other Selection Considerations

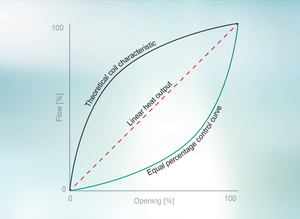

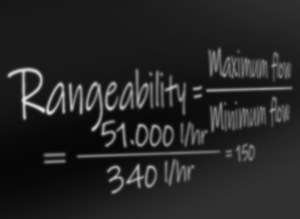

By now, this FlowCon Topic Letter, should hopefully have provided a good insight to the fact that authority is important and is useful when selecting the proper control valve. Next to authority, it is equally important to consider control valve characteristic, rangeability and turndown ratio which are covered by other FlowCon Topic Letters.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs