Composite Perks - Why use Composite in PICVs?

By Torben W. Ibsen, President, M.Sc. (Mech.Eng.), FlowCon International ApS, Denmark - 01.2020

PICVs installed because of Accuracy

Since the introduction of FlowCon’s very first and revolutionary PICV in 1993, they have become the mainstream solution for modern buildings were energy and indoor climate optimization is paramount, which in turn supports building productivity. The main argument for installing PICVs in HVAC systems is the extremely accurate pressure independent controls performance with 100% authority at all times, which provides precise temperature control with minimal energy consumption.

Given that the justification of PICVs is increased HVAC system control accuracy - leading to reduced energy consumption and increased building productivity - it goes without saying that the accuracy of the PICVs is essential to benefits gained from using such. Put simply, the more accurate the PICV, the more accurate the controls and the larger the benefits.

In order to make the PICV as accurate as possible and maximize the benefits, the manufacturing processes and sub-component materials used, are critical.

Composites result in higher Accuracy

The requirement for scale resistance and accurate complex geometries makes composites the perfect fit. When using composites, they can be designed to cope with the precise physical conditions the valve is exposed to regarding water quality, temperature etc., while simultaneously ensure extremely high accuracy and repetition in the production process through injection molding. The high specification glass-reinforced components used by FlowCon, in conjunction with the injection molding process - ensure a constant material shrinkage of less than 0.3%, whereas brass generally holds shrinkage values of around 1% if hot stamped, depending on material configuration.

Using composites furthermore allows material composition to prevent scaling on the vital parts, increasing dirt resistance and protecting the accuracy over time.

Some PICV manufacturers, (unlike FlowCon) use steel components over the regulation element, even though they are using composites as sub-components elsewhere in the valve. However, they either do not include the valve accuracies or list tolerances that are significantly higher than the ones listed in all FlowCon literature and verified by 3rd party reports. And therefore, dismissing one of the critical reasons for using PICVs in the first place, namely improved valve accuracies.

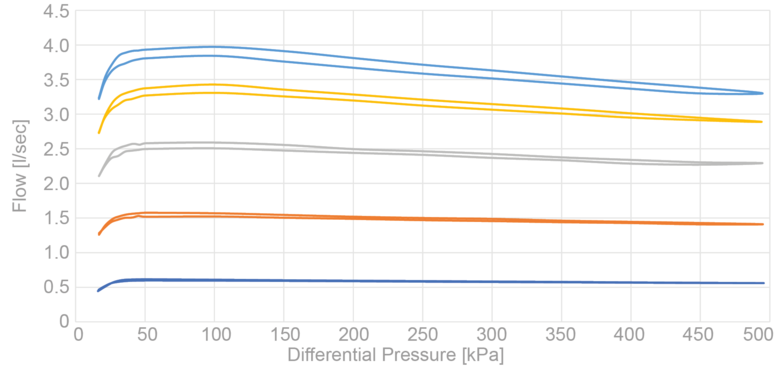

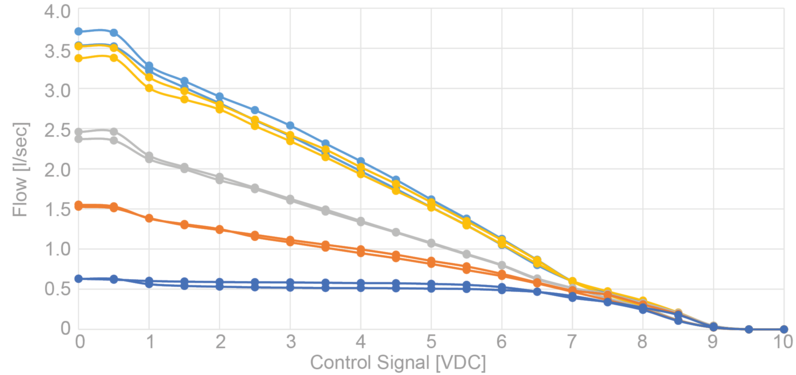

Pressure Independency: PICV FlowCon Green.3 at setting 1 to 5, BSRIA 3rd party verified, test report 100830/1.

Read more

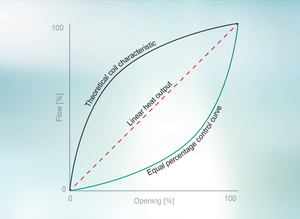

Control Curves: PICV FlowCon Green.3 with FH-actuator (Linear Control Mode) at setting 1 to 5, BSRIA 3rd party verified, test report 100830/1.

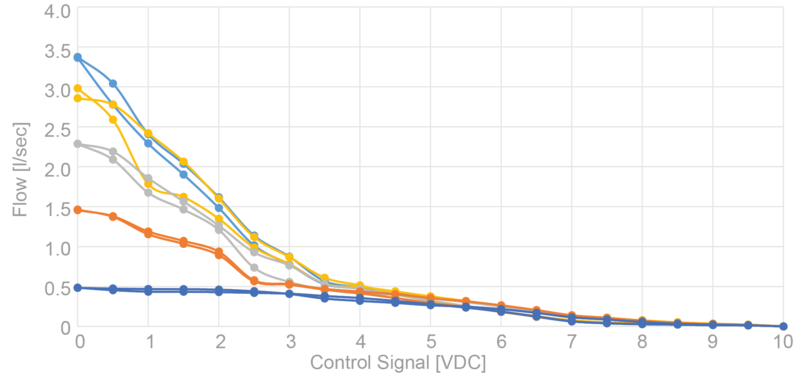

Control Curves: PICV FlowCon Green.3 with FH-actuator (Equal% Control Mode) at setting 1 to 5, BSRIA 3rd party verified, test report 100830/1.

Please note, that 1% increased PICV accuracy can be converted to a reduction of approximately 0,5% in the buildings overall HVAC energy consumptions - accuracy does matter and selecting a good accurate PICV does pay off.

Any Risk when Introducing Composites?

FlowCon International has used composites in various heating and cooling applications since the 80’ies without any complications on function or life. Composites do hold slightly lower yield strength than steel and brass but do note, that most HVAC products contain rubber components, including PICVs, which typically include an EPDM or HNBR diaphragm. The rubber components are generally more fragile than the composites installed meaning that the general robustness of the product - in terms of water quality, chemical sensitivity, pressure etc. - is primarily defined by rubber and not by the yield strength of high-tech composites designed for water born HVAC application. The composites’ yield strength is by far exceeding the requirements for such applications and is more importantly designed to operate in the temperature range used in HVAC installation and at the same time be scale resistant. Particularly, the scale resistance is seen to be a problem in many brass valves, which are facing scaling on their sensitive elements, hampering the product’s long-term performance - this is avoided when using high-tech composites.

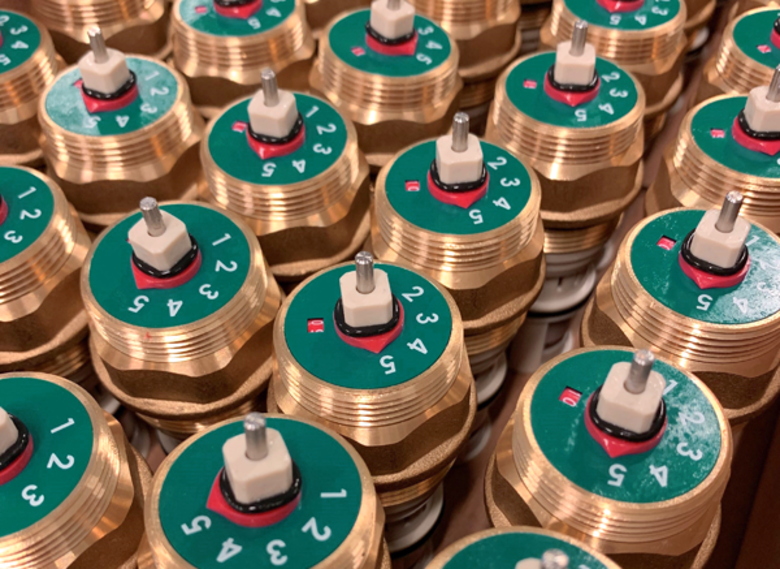

The composites used by FlowCon are high quality engineered state-of-the-art materials designed and produced to the highest standards, which is proven by the fact that FlowCon is the only manufacturer, who have separated the PICV into 2 different components: a brass retainer and a stand-alone composite PICV insert with a build-in diaphragm. No other PICV valve manufacturer produces the internals strong enough to be handled as an individual component, although this provides great flexibility to the valve usage and serviceability after installation. High standard composites have proven superior to metals, even the more noble metals like aluminum, titanium, etc. in critical applications such as car-, aerospace- and space industries.

There is little doubt that specially designed composites are the future - not only in the aerospace industry - but also in high-tech HVAC applications requiring optimal product performance.

High-Temp Composite replaces Titanium on Nasa’s Shuttle Successor

TenCate Advanced Composites developed a heat resistant composite material that is being used to provide a heat shield and backshell structure of the Lockheed Martin Orion multi-purpose manned spacecraft, currently being tested and developed by Nasa.

The composite material has replaced what was initially earmarked to be a fully titanium structure, used to provide shielding to the space capsule during re-entry.

There is little doubt that specially designed composites are the future - not only in the aerospace industry - but also in high-tech HVAC applications requiring optimal product performance.

FlowCon Valve Design and Material Selection → Your Advantages

Utilizing composites allows the product to be designed to the exact applications intended for in terms of strength, temperature, fluid composition and performance, resulting in superior product features. To summarize, the advantages of the construction offered by FlowCon International are:

- Accuracy in manufacturing allowing confirmed product accuracy in technical literature.

- Repeatability in production making the products highly uniform.

- Full stoke control at all pre-settings.

- Strength as the construction is so robust that the internal is designed and delivered as an independent insert.

- Flexibility through all project stages due to insert-design:

- Design is simplified as piping dimensions and flow rates are largely independent. This furthermore means, that the inserts can often be ordered late in the process.

- Installation is made more efficient as each component can be installed by the profession specialists i.e.:

- Valve housings can be handled by the mechanical contractor / pipe fitters.

- Inserts can be handled by the commissioning team, who may also set the flow before going on ladders mounting the insert.

- Actuators can be handled by the electrical contractor.

- Flushing can be done following various strategies. Please refer to the topic letter covering water quality requirements.

- Service in case of any service issues, changed layout, etc., the valve can be serviced through the insert alone. There is no need to dismantle the valve from the piping system.

The composite-based insert is in other words improving construction productivity and reducing maintenance issues drastically.

Composites - Low-Cost Alternatives?

Composites are not cheaper than brass, stainless steel and other metal if a proper compound is used. Our compounds are virgin and from the highest quality sources. The cost of the high-tech composites used by FlowCon is actually more than 3 times the cost of brass.

The added cost of composites can for instance be seen in the automotive industry, where cars made of composites such as carbon fiber, are significantly more expensive than standard steel or even aluminum cars.

Conclusion

Composites have been used by FlowCon in balancing valves for more than 25 years and are being used in multiple applications in multiple industries for years, including the HVAC industry - a usage, which is only increasing. Composites allows the best performance in the parameter the PICV are exposed to and allows superior accuracy. The unmatched accuracy provides the best energy efficiency in the industry, which are essentially the reason for installing PICVs. The insert-based technology furthermore provides a variety of advantages throughout the construction process and maintenance process.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

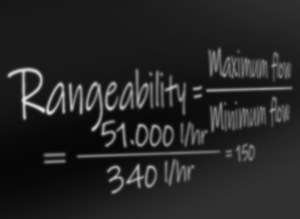

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs