Do’s and Don’ts related to

Pressure Independent Control Valves, PICVs

By Christina Cohr, CCO, M.Eng (Export), FlowCon International ApS, Denmark

02.2024

Pressure Independent Control Valves, commonly referred to as PICVs, have gained widespread acceptance in the HVAC industry as the preferred method of terminal control in variable flow systems. This is primarily due to their energy-saving potential. FlowCon International has been a leading supplier of PICVs for decades and is credited with pioneering PICV technology, which was first developed in the late 1980s. FlowCon introduced the world's first PICV in 1994.

This Topic Letter is a Collection of Answers to questions related to PICVs, but not directly on PICVs. These are questions that we have received from the market over the years. If you want to understand how to selection your PICV, we refer to FlowCon's Topic Letter 'How to Select a good PICV' and other relevant articles.

Do you need a balancing valve with a PICV?

It is a fact, that the full range of FlowCon PICVs are pressure independent balancing and control valves also referred to as PIBCVs. This means that they have a built-in dynamic balancing mechanism. And therefore, you will not need additional balancing valves when working with our PICVs. Some other PICV brands on the market lack the integrated dynamic balancing function and consequently they can only obtain system balance electrically resulting in added wear on the actuator. In other cases, a separate balancing valve is added, but having two separate valves in a 'set' will result in an authority conflict.

With a true PICV – like FlowCon's – you obtain the optimal balancing and control nonmatter the required load. And as they are one valve, valve, you will not experience any authority clash.

When do you need a pressure control valve?

A Differential Pressure Control Valve (DPCV) could be essential for various reasons depending on the specific application and system design. This could be system protection, noise minimization, pressure stability and zone control. In many modern HVAC systems, particularly those with variable flow strategies and a focus on energy efficiency, PICVs are favored for their ability of pressure independent and accurate flow control at lower pump head and therefore DPCVs are as such not required, when using PICVs in your system. A decision to use DPCVs alongside PICVs should be based on a thorough system analysis and the specific needs of your application, as adding unnecessary components to an HVAC system will only increase installation and operating costs and complexity.

Read more

Why use a 2-port valve?

Historically, it was common years back to have the system control performed by 2-way control valves. But as indicated by the name, these would only control and not balance. To achieve reasonable system balance with a conventional 2-way control valve, it would require the addition of a balancing valve with each control valve and a DPCV on the zone. Working with more valves per terminal unit instead of only 1 (PICV), obviously affects to overall installation cost and actual pressure drop, but also the commissioning practice. To ensure design flow for each terminal unit the commissioning process would include numerous adjustments of each DRV's flow setting. Every flow adjust must be followed by verification of flows and differential pressures in the zone and if necessary, re-adjusted to achieve balance. Unfortunately, long-lasting system balance was rarely obtained.

Also, a 3-valve-solution will most likely result in an internal authority conflict. Control valves within the system attempt to regulate flow- or control conditions simultaneously and their interaction would affect one another, and the numerical estimate would consequently take longer time. Such conflict results in inefficient or inconsistent system operation, which potentially would lead to temperature imbalances, energy waste, and reduced comfort. When using true PICVs, you will obtain 100% authority and no conflicting as each PICV will have full control over its regulation. With a pressure independent solution, you will achieve the most energy efficient solution which benefits not only your wallet (the energy usage is lower), but also the environment (as carbon footprint is reduced).

What is the difference between a pressure dependent and a pressure independent control valve?

It is important to know whether the control and balancing functions chosen work pressure dependent or pressure independent. The conventional 2-port control valve is a pressure dependent valve. And the balancing valve mentioned in the earlier section can be either a static balancing valve or a dynamic balancing valve. A static valve – also known as manual DRV – is a pressure dependent valve and therefore flow output will change if system pressure changes. The dynamic balancing valve works pressure independently and will secure that flow output remains constant even if changes occur in the system pressure. But again, separating balancing and control over two valves will result in an authority conflict and high pressure drops, and therefore our recommendation is a PICV-solution.

Need more Information….?

Contact FlowCon and gain knowledge from our expertise with Pressure Independent Control Valves and reach out for further details or guidance in choosing the proper PICV. All our PICV solutions are 3rd party tested according to BSRIA BTS 01 standard which includes Pressure Independency, Accuracy, Repeatability, Control Characteristics and Seat Leakage.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

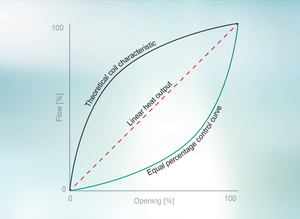

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

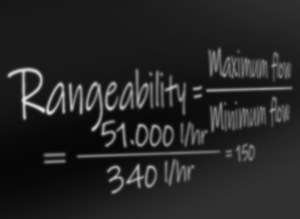

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs