How to Select a good PICV?

By Christina Cohr, CCO, M.Eng (Export), FlowCon International ApS, Denmark

09.2023

Pressure Independent Control Valves (PICVs) are nowadays widely accepted in the HVAC industry as the best method of terminal control in variable flow systems due to the energy saving possibility. FlowCon International has been supplying PICVs for decades – in fact, FlowCon invented the PICV technology back in the late 1980’ies and introduced the world’s first PICV in 1994.

This Topic Letter focuses on correct physical PICV-selection for your HVAC application. Obviously, there are several essential PICV characteristics within Pressure Independency which need to be considered during the selection process. These include Accuracy, Repeatability, Control Charac-teristics and Seat Leakage, all of which are covered in other FlowCon Topic Letters.

How do I choose the proper PICV?

There are four key application requirements which are important when choosing a PICV: pipe size, design flow, pressure drop and control type.

The FlowCon design concept means that the valve body size is selected independently of design flow because each PICV insert fits in more than one valve size. Therefore, we recommend that priority is given to the required flow which is the main purpose of any PICV. Some other PICV-brands in the market link pipe size and flow. For example, with a required design flow of 0.008 l/sec the only valve size available is a DN10, or on the other hand at a flow of 0.7 l/sec a DN25 valve body is the only option. FlowCon’s insert-based PICV solution offers ultimate flexibility, allowing for flow rates from 0.005-0.736 l/sec to be selected in DN15, DN20 or DN25 valve housings and therefore matching pipe sizes on site.

Selection Steps to a good PICV:

- What is your design flow?

0.00482-76.8 l/sec (0.0763-1220 GPM)

- What is your pipe size?

DN15-DN250 (1/2”-10”)

- What is ΔP at index unit?

16-800 kPaD (2.3-116 psid)

- Which control is required?

Electrical or thermal actuator

Modulating, 3-point floating or 2-position control

Signal controlled or BUS controlled

Failsafe or standard actuator

Read more

With ever improving efficiency in building design, it is equally important to have very low flow possibilities for heating systems, as it is to have high flows. FlowCon’s full PICV flow range goes from low flow rates to high flows, 0.00482-76.8 l/sec (0.0763-1220 GPM). Also, for installation, selection and logistic purposes, it is extremely convenient if the same valve can cover a wider flow range.

After the flow rate selection is satisfied, the next task is to choose a valve size that suits the system design. Our complete PICV size range covers DN15-DN250 (½"-10").

What is the pressure range of a PICV?

Originally, there were separate ranges for low- and high-pressure application of PICVs. However, currently we offer one wide pressure range, which makes selection much easier for the HVAC practitioner.

The smaller sizes (threaded DN15-32, ½"-1¼") work in a ΔP range of 16-800 kPaD (2.3-116 psid). Medium sizes (threaded DN40-50, 1½"-2") have 16-600 kPaD (2.3-87 psid). And for the larger versions (flanged DN50-250, 2"-10") the pressure range is 30-800 kPaD (4.5-116 psid).

Essentially, with a wide pressure range, the focus should be on the minimum ΔP required to make the PICV operate correctly and not the upper values of the ΔP range, which is more than enough to satisfy the needs of the HVAC sector. To operate satis-factorily, the PICV requires a minimum differential pressure to activate diaphragm mechanism within the PICV, enabling the valve to be pressure independent. During commissioning, the pump is trimmed so that only ΔPminimum is available at the PICV on the index circuit at 100% load (= design flow). This way, the system is properly commis-sioned and will run at lowest possible energy consumption. For ΔPmax, it is confirmed to be within the valve’s ΔP range to ensure that the PICV operates effectively under part load conditions.

How do I select the correct actuator for my PICV?

A true PICV design should allow for full stroke modulating control at all flow settings without any stroke limitations – this will provide better actuator accuracy and flow control at partial load. Some PICV designs use the stroke of the actuator stem to set the flow rate, resulting in limited stroke and consequently limited control. This is a real concern at low flow rates and can lead to the PICV effectively working as an ON/OFF valve, regardless the presence of a modulating actuator. Therefore, it is important to select your PICV with full stroke length independent of selected flow setting.

If, on the other hand, working with a multi-rotation actuator, the reduction of a selected rotating degree is much less affective, considering the actuator's full span of 2160° or more.

Electrical modulating control will provide the optimal regulation at any load condition and is the preferred choice. Most PICV manufacturers offer standard electrical modulating actuators as failsafe and bus-communication versions.

How do I adjust my PICV?

When it comes to setting or adjusting the PICV, this manual procedure impacts the valve's accuracy. Therefore, it is preferred to have a stepless setting. This will make finetuning possible and allow to get closer to design flow and thereby lower the setting tolerance. Narrow flow tolerances have a positive impact on the building's energy consumption. In fact, measured over time, 1% increase in PICV accuracy will result in a reduction of ~0.5% in the building’s overall hydronic energy consumption.

FlowCon's threaded PICVs are set with an adjustment key. Setting is stepless and can be changed with the system running if required. The combination of the insert design and the wide setting range located on the top of the unit adds to the overall flexibility. Once set, the scale setting is 'hidden' with the actuator fitted, which acts as a tamper-safe solution.

For FlowCon's flanged PICVs, flow setting is set directly on the control actuator. Setting values are pre-programmed and therefore not stepless. On the other hand, the electronic setting will secure identical setting result every time, eliminating the setting tolerance. These valves' max. flow setting can also be changed during system operation and the build-in password protection makes the flow and other settings fully tamper-proof.

How do I service my PICV?

To obtain a preferable high repeatability, the valve control opening area should be identical from valve to valve throughout each flow setting. The shape of the control opening area can be different depending on the valve design and manufacturer. Nonmatter, the shape, FlowCon suggests that the VDI 2035 Guideline's industry recommendations on water quality are followed.

In case debris gets caught in the opening area, the FlowCon insert-based PICVs can easily be serviced, rinsed, or replaced if needed. Service will, in other words, not require any tampering of the pipework but merely a handling of the insert itself. Isolation of one valve for insert service can be done even with the main system still in operation. Even FlowCon's larger PICV valves can be disassembled and serviced directly.

Need more Information….?

Contact FlowCon for more information or help to select your proper Pressure Independent Control Valves, you can also read more about PICV solutions in cooling and heating. All our PICV solutions are 3rd party tested according to BSRIA BTS 01 standard which includes Pressure Independency, Accuracy, Repeatability, Control Characteristics and Seat Leakage.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

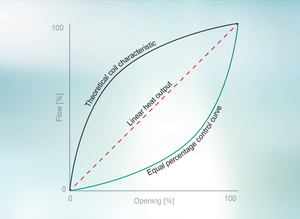

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

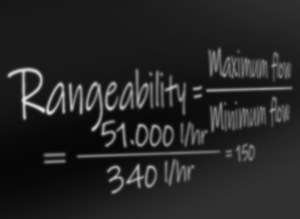

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs