Points for LEED Certification using

Pressure Independent Control Valves, PICVs

By Torben W. Ibsen, CEO, M.Sc. (Mech.Eng.) and Christina Cohr, CCO, M.Eng (Export), FlowCon International ApS, Denmark

11.2023

LEED certification from the U.S. Green Building Council is used to document a building’s sustain-ability including among other things indoor comfort, energy consumption and product embodied carbon. On these tree parameters, using FlowCon PICV valves will help to secure LEED rating points.

The LEED certification is constructed as a points system, where different initiatives including improving the building’s indoor climate and/or reducing the energy consumption are being rated. The score will hereafter define the rating of the building, i.e. the higher the points score, the better overall classifi-cation can be achieved.

The FlowCon PICV range holds attributes that will help to secure LEED rating points, although it is important to understand that PICVs are one of many components being rated to achieve an overall rating. Consequently, using PICVs will not on their own guarantee points and a high classification rating, but will help in obtaining these.

Latest version of LEED v4.1 (covering Building Design and Construction, BD+C) was released in July 2019 and focuses not only on healthy, effi-cient, and cost-saving buildings, but also on carbon emissions.

LEED v5 is on its way and will focus even further on decarbonization, resilience and eco-systems.

The points, where FlowCon PICVs can complement other system equipment and thereby improve the possibility of being granted points for the LEED certification are as follows:

Energy and Atmosphere, EA

EA Prerequisite 1: Fundamental Commissioning and Verification

This section is an absolute requirement, which the PICVs can help achieve.

Commissioning of PICV valves can be done easily either directly on the valve or from the BMS system via BUS communication to the valve actuators.

For some FlowCon PICVs, their display actuator allows for immediate monitoring of the flow rate on the actuator itself. But remote monitoring and verification of PICV valve performance are available on all FlowCon PICVs and can be done either directly or with BUS communication. With a direct feedback signal on valve position to the BMS system, the BMS will know the current flow rate. With either BACnet or Modbus communication from the PICV actuator, a wider range of data points are available to the BMS allowing for full monitoring of valve performance.

All together, these data are used to verify that the flow through each coil or thermal unit is as specified by the consultant engineer.

EA Prerequisite 2: Minimum Energy Performance

Minimum energy performance is also a mandatory requirement.

The energy performance of the building will be substantially improved when using FlowCon PICVs because of the overflow prevention these units provide, in both fully open and partly open condition. Furthermore, the PICVs will provide 100% authority and be independent of pressure fluctuation in the system, caused by variations in load conditions or pump operational frequency.

The energy performance will be substantially better compared to conventional solutions consisting of 2-way control valves and DRVs. The FlowCon PICV solutions will provide improvements to system pumps due to reduced system pressure drop, prevention of overflow during both partial and full load situations. The accurate control of the water flow in all valve positions within the assigned differential pressure range will furthermore increase the ΔT across the coils and thereby increase the chiller efficiency as well as reduce the pump frequency.

EA Prerequisite 3: Building-Level Energy Metering

The FlowCon PICV solution including BUS actuators can provide monitoring of energy consumption if fitted with temperature sensors. This information is conti-nuously transferred to the BMS system and with this data the BMS system can calculate overall building energy usage on daily basis and continuously.

Read more

EA Credit 1: Enhanced Commissioning (up to 6 points)

This section contains amongst others a requirement of 10 months’ operation review, which the remote monitoring of the valves will allow through the BMS system. A log of valve performance can be created if programmed into the BMS system. In additional, the feedback signal can be used to notify of possible valve failures, and thereby proactively alert the maintenance personnel of possible problems.

EA Credit 2: Optimize Energy Performance (up to 18 points)

Commonly, PICVs are equipped with measuring points to confirm pressure drop across the valve. During commissioning, the pump should be trimmed to allow only the required minimum differential pressure at the system’s index coil. This will result in a system setup which at full load uses only the required pressure and nothing more. During partial load, the variable frequency drive (=VFD) pump will reduce speed and let the pump run at a more efficient point of its performance curve corresponding to the new reduced load requirements. Likewise, the chiller will operate at its optimized coefficient of performance, COP. And with the PICVs’ unique pressure independency, they will not be affected by system pressure changes, and will automatically adjust its orifice and reduce flow matching the lower load conditions.

EA Credit 3: Advanced Energy Metering (1 point)

By using FlowCon PICVs the system flow rates can be continuously monitored externally, allowing for data comparison between the actual performance and the predicted performance.

Materials and Resources, MR

MR Credit 1: Building Life-Cycle Impact Reduction (up to 5 points)

PICVs are not only of beneficial use in new constructions but is certainly also welcomed during refurbishment and complete renovations of existing buildings. With the unique insert concept which FlowCon offers on all smaller PICV valves, reuse of flushing caps and valve housings is a possibility. The innovative PICV working is built into the insert, which can be replace for service or change-out without tampering with the pipework.

At the end-of-life-stage, FlowCon insert based PICVs can easily be separate for correct material sorting, proper recycling and recovery and thereby minimized waste.

Both will support positively in a building’s LCA.

MR Credit 2: Environmental Product Declarations (up to 2 points)

For all PICV valves, FlowCon can provide a CO2 invoice which documents each product’s embodied carbon.

Indoor Environmental Quality, EQ

EQ Credit 5: Thermal Comfort (1 point)

The FlowCon PICVs valve will increase the accuracy in the water flow control and the pressure independent function will improve the temperature stability. In conventional solutions with 2-way control valves and DRVs, pressure fluctuations will lead to flow fluctuations, which in turn will cause temperature fluctuations. To summarize, the pres-sure independent function, in combination with the overflow protection, will maintain the correct temperature in the zone.

The feedback feature ensures that the valves can be directly integrated into a permanent monitoring system to ensure that the building performance meets the desired comfort criteria.

Innovation, IN

IN Credit 1: Innovation (up to 5 points)

It is a possibility to link the FlowCon PICVs to the VFD pump and thereby ensure the optimal operation and improved efficiency. The valves have the innovative feature, allowing for the BMS system to monitor the actual flow rate without considering the exact differential pressure. It furthermore has the option of direct verification regarding among other actual valve performance, energy consumption, possible error codes and statistics, which can be used for addressing building maintenance.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

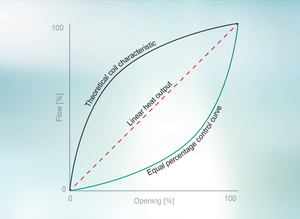

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

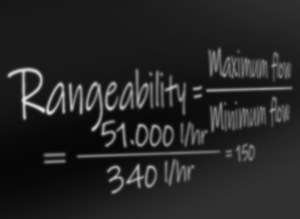

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs