Recommendations on Water Quality

By Christina Cohr, CCO, M.Eng (Export), FlowCon International ApS, Denmark - 09.2019

What is Proper Water Quality in HVAC systems?

Consultant engineers and mechanical contractors must be aware of local water conditions and take appropriate precautions to ensure that the media quality in the HVAC system is satisfactory. Poor water quality and corrosion may result in reduced system functionality, leakage, components clogging (hereunder valves and heating/cooling coils), loss of heat transmission and flow noise.

When designing and installing closed-loop hydronic systems, several things should be considered. Field experience shows that risk of valves and coils clogging, is greatly reduced when the following steps are taken:

- Flush the system before installing the valves.

- Install strainers in front of the valves to protect against clogging. Obviously, strainer baskets must be installed, checked and cleaned as required during flushing and normal operation.

- Use clean water according to the guidelines in VDI 2035. VDI 2035 recommends water quality as per conductance value <100 μS/cm, oxygen content of up to 0.1 mg/l, pH of 8.2-10.0 and requires low turbidity <1FTU and consequently low content of alkaline earths.

- If using any additives, please contact FlowCon for guidance. It is advisable to work without chemicals.

FlowCon works with

Three Flushing Strategies:

1: Flush with the Regulation Element present:

If a complete valve is installed prior to flushing, then a strainer (with basket) should also be installed upstream. The strainer basket should be examined continuously throughout the entire process and cleaned if necessary. Both forward and back flushing are generally accepted (please refer to product literature for advice).

2: Flush without the Regulation Element present:

The unique removableinsert-based solution offered by FlowCon allows flushing prior to installing the regulation element. Install valve housing with a flushing cap and perform proper system flushing, (which can be full force forward or backward). Then the commissioning team sets design flow on the insert and installs it into the housing. Such procedure will greatly reduce time spend on cleaning baskets, as centrally located strainers may be used for dirt collection. This two-step procedure can furthermore be used as procedure validation, by requesting a flushing and water quality report prior to installing the insert.

3: Flush through Flushing By-Pass Unit:

Using a FlowCon by-pass solution will accept forward and back flushing, as well as isolation of the FCU to perform system flushing. This solution will also offer major benefits during maintenance and service periods.

Benefits

FlowCon offers a wide range of insert types to suit any application in a HVAC system. FlowCon insert solution is a benefit during selection, installation, flushing, commissioning and maintenance.

Download Article

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

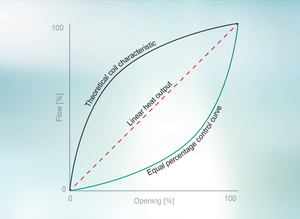

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

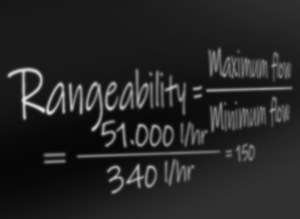

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs