Sustainability and PICVs

By Christina Cohr, CCO, M.Eng (Export), FlowCon International ApS, Denmark - 09.2025

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design. The global HVAC industry sits at the center of the energy efficiency debate, with heating and cooling systems accounting for a significant share of worldwide energy use and emissions.

Even incremental gains in system efficiency can result in measurable environmental benefits. Within this context, Pressure Independent Control Valves (PICVs) have become the industry standard for terminal control in variable flow systems, thanks to their proven ability to support energy savings and sustainability targets. FlowCon International has been at the forefront of this development, pioneering PICV technology as early as the 1980s and introducing the world’s first PICV in 1994. Since then, PICVs have evolved into a cornerstone of modern HVAC design - recognized not only for their efficiency, but also as a critical enabler of sustainable building performance.

At FlowCon, we believe sustainability goes beyond energy performance. True sustainability requires a holistic view across the entire product life cycle - from design and material sourcing to installation, use, service, and end-of-life. This is why we design and manufacture our PICVs with sustainability integrated into every stage. Guided by the 7R Sustainable Strategy, we strive to minimize environmental impact, strengthen the circular economy, and maximize long-term value for our customers - all while ensuring uncompromised system performance.

This Topic Letter focuses on the Sustainable Benefits of working with PICVs. Naturally, it is also essential to consider valve characteristics and performance when selecting your PICV, but these aspects are covered in detail in other FlowCon Topic Letters.

Sustainable Benefits of a good PICV:

FlowCon’s commitment to sustainability goes beyond energy savings and we embed sustainability into every step of the product life cycle: from design and production to service and end-of-use. A good PICV is more than a control device - it is an enabler of sustainable building performance, a tool for reduc-ing material and waste, and a contributor to the circular economy. With FlowCon PICVs, sustainability is not an add-on - it is built in.

1. Re-Think

Re-thinking is not just a design principle; it is the foundation of FlowCon’s business philosophy. By re-examining conventional HVAC design, we continually innovate to achieve smarter, lighter, and more efficient solutions.

Our Engineering team focuses on:

Material optimization, ensuring every component serves a purpose.

Packaging minimization, reducing transportation emissions and waste, while still ensuring adequate product protection.

System-level thinking, integrating PICVs as enablers of overall HVAC efficiency.

The outcome of this mindset is fewer resources consumed, longer-lasting solutions, and lower environmental impact across the board – and RE-THINK is throughout the organization our overall favorite, which directly links to REDUCE.

Read more

2. Refuse

In a market where size and weight historically were not that important and excessive material use have long been standard, FlowCon chooses differently.

We actively refuse unsustainable design practices and prioritize:

Durable materials with proven longevity.

Valve design with disassembly and recyclability in mind.

Valves engineered with high accuracy and good repeatability

This deliberate refusal of wasteful practices is central to our sustainability commitment.

3. Reduce

FlowCon PICVs directly contribute to reduced energy use by ensuring accurate and stable flow control at all loads. Stable system balance means HVAC installations operate closer to their design intent, avoiding overflows and inefficiencies.

Beyond system-level energy savings, reduction is also embedded in the product concept itself:

Reduced material waste during production.

Reduced full replacement needs thanks to modularity.

Reduced CO2 footprint across the value chain.

4. Re-purpose

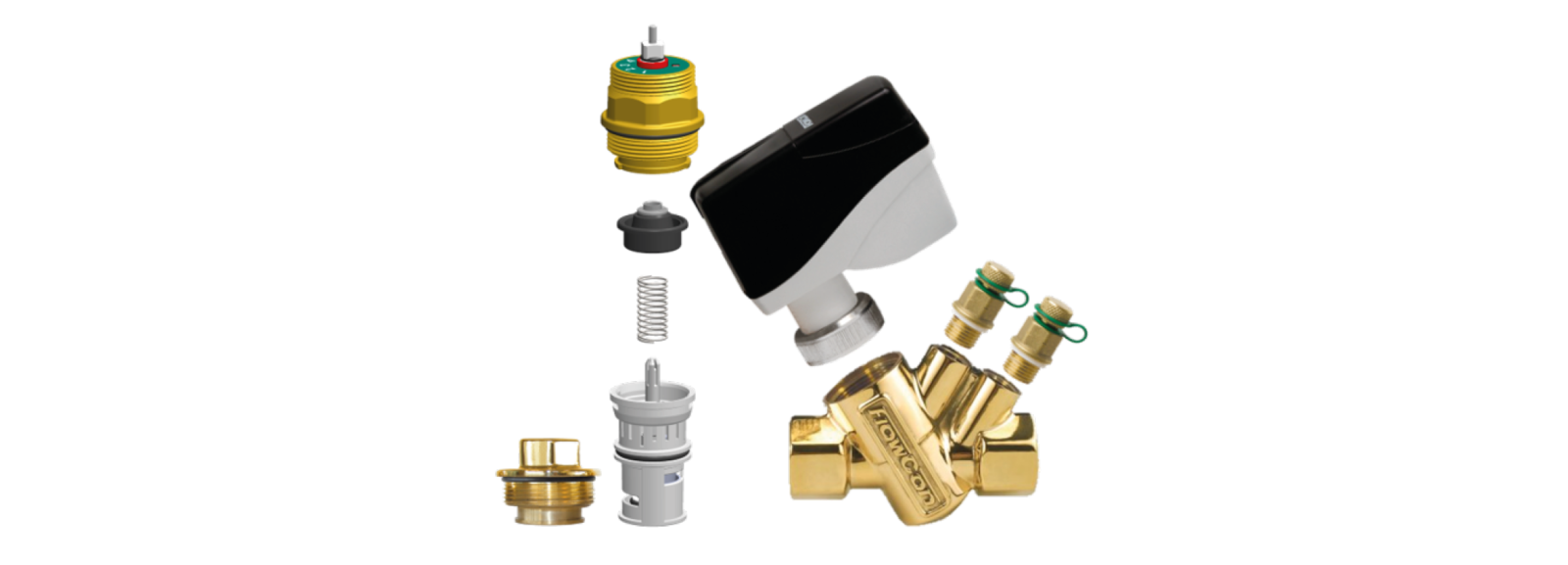

FlowCon’s modular valve design allows components to be re-purposed for different projects and applications. This adaptability gives project owners and service teams greater flexibility while reducing the need for entirely new components.

Flushing caps are prime examples: they can be carried over and re-purposed for use in new projects, supporting longer product life and lowering lifecycle costs.

5. Re-use

With the FlowCon insert concept, RE-USE becomes not just possible but practical. Flushing caps can be re-used from project to project without compromising performance - the same actually also goes for valve housings.

This capability supports a circular economy mindset, where components are kept in circulation rather than prematurely discarded.

6. Recycle

End-of-life is often where products fail the sustainability test. At FlowCon, we take a different view: end-of-life is a resource opportunity.

FlowCon’s insert-based PICVs are engineered to be easily separated into material fractions:

The valve housing can be sold for recycling being 100% brass (or re-used in a new project).

The flow regulation unit or the insert, which we call it, can be taken out of the valve housing and with a simple twist separated and properly sorted and recycled.

The flushing cap can be re-used or recycled depending on condition.

The electronic actuator can be returned through the WEEE program or correctly recycled locally.

This insert-based valve design for disassembly ensures that FlowCon valves do not become waste products but rather contribute to circular material flow.

7. Repair

In the HVAC industry, the seventh “R” is REPAIR, replacing “Rot” from the bio-industry cycle.

FlowCon valves are designed with maintainability in mind:

Smaller valves: typically, it is sufficient to re-place only the insert rather than the entire valve, allowing for a smooth replacement without pipework tampering and resulting in significantly reduced downtime.

Larger valves: often on-site repair is possible, reducing downtime, transportation and waste.

This approach commonly enables a 50/50 balance between replacement and repair, ensuring that service operations minimize environmental impact while maximizing asset value.

At end-of-use what do I do with the PICV?

One of the most important aspects of FlowCon’s sustainability philosophy is how we view products at the end of their service life. Rather than discarding a PICV as waste, we design them to be resources for future use. By enabling re-use, re-purpose, and recycling, we close the loop and strengthen the circular economy.

This perspective aligns with the broader sustainability goals of the construction- and HVAC industries, ensuring that FlowCon PICVs are not only tools for energy efficiency today, but also contributors to material efficiency tomorrow.

It is essential to us, that PICVs are not just considered a waste product at end-of-use, but rather a resource which can be re-used elsewhere in the material value chain, which is why we refer to end-of-use rather than end-of-life.

Environmental Compliance Data

Stricter sustainability regulations, green building certifications such as LEED and BREEAM, and rising corporate ESG expectations (Environmental, Social, and Governance) are transforming the HVAC industry.

Sustainability in HVAC is a shared responsibility and covers the full value chain. Downstream:

Building owners seek to safeguard long-term asset value, mitigate risk, and demonstrate ESG compliance.

Consultant engineers challenge to design systems that not only deliver precise thermal control but also minimize environmental impact from construction through decades of operation, maintenance, and eventual replacement.

Contractors select products that combine high performance with transparent, third-party environmental data.

Service- and maintenance teams face expectations around serviceability, repairability, and ease of disassembly and recycling at end-of-use.

By adopting circular thinking, also the industry is shifting from an end-of-life mindset to an end-of-use approach. This encourages stakeholders to extend product lifespans, reduce waste, and prioritize reuse and repair wherever possible. Such practices are not only environmentally responsible but also support regulatory readiness, protect corporate reputation, and improve long-term cost efficiency. In short, a holistic, lifecycle-driven sustainability strategy is rapidly becoming the standard for responsible and future-proof data center design.

Environmental Product Declarations (EPDs)

As sustainability regulations grow more complex, transparency is no longer optional - it is essential for responsible decision-making across the HVAC value chain. From initial design to eventual decommissioning, every product and component must contribute to both operational performance and demonstrably lower environmental impact.

This is where Environmental Product Declarations (EPDs) play a critical role. EPDs are third-party verified documents that provide transparent data on a product including:

Embodied carbon

Recyclability

Overall environmental performance

By making this information accessible and credible, EPDs empower stakeholders to make sustainability-driven choices at every stage of a project.

For building owners, EPDs enable greener investment strategies and demonstrate compliance with ESG commitments.

For contractors - whether mechanical, electrical, or commissioning - EPDs streamline sustainability documentation and reduce uncertainty in project approvals.

For the entire project team, EPDs contribute directly to certifications such as LEED and BREEAM, embedding sustainability as an integrated part of both design and delivery.

Need more Information….?

FlowCon’s commitment to sustainability goes beyond energy savings - it is built into every stage of the product life cycle. A good PICV is more than just a control device; it enables sustainable building performance, reduces waste, and supports circular economy.

Contact FlowCon for guidance on selecting the right Pressure Independent Control Valve. All our PICV solutions are 3rd party tested to BSRIA BTS 01 standard covering Pressure Independency, Accuracy, Repeatability, Control Characteristics and Seat Leakage.

Latest FlowCon Articles

See all

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design

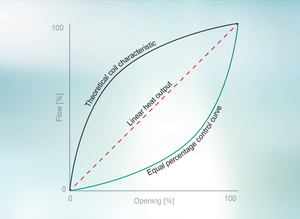

Importance of Control Curves in PICVs

Equal percentage control vs. linear control – which is better when and why?

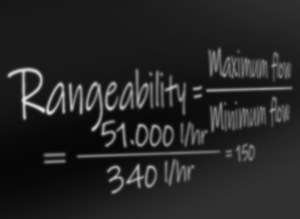

Rangeability and Turn Down Ratio - Update

Definition and use of Rangebility, Resolution and Turn Down Ratio in FlowCon PICVs