New Stronger FlowCon EVS Insert

FlowCon introduces a next-generation-version of the FlowCon EVS-insert.

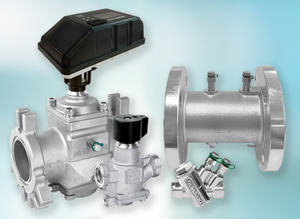

Naturally, the new EVS-insert will fit in the same valve bodies as the previous one, i.e. A15/20, AB15/20 and ABV1 (DN15/20/25) and apply with the same range of actuators (EV.0.2-EV.0.5).

The new stronger EVS-insert is launched to avoid the risk of breaking the flexible grips due to rough handling and avoid possible risk of leakage through the slots in the flexible grips.

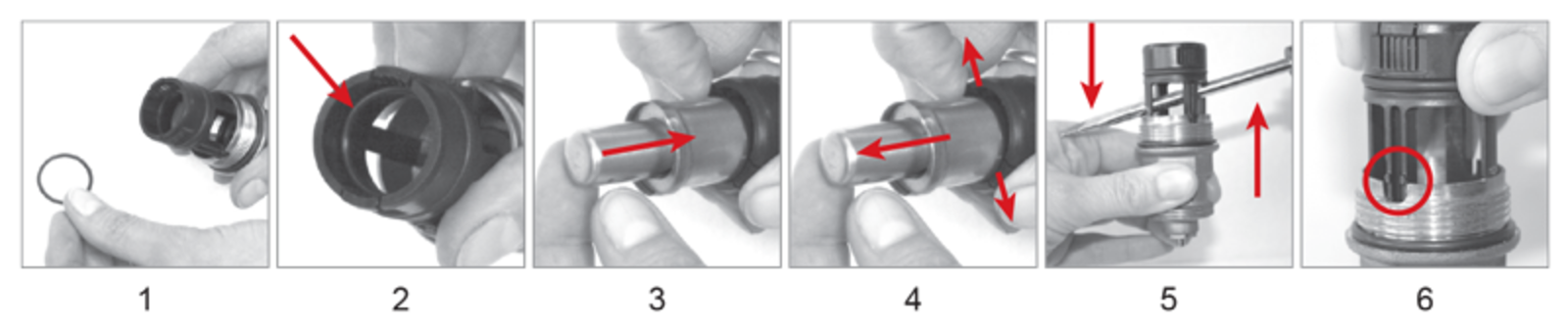

Procedure of installing the stainless steel cartridge in the new EVS-insert remains unchanged and is as follows: Take the cartridge o-ring (Photo1) and place it on the internal edge (Photo2). Afterwards push the 3/4” stainless steel cartridge (bottom first) into the EVS-insert (Photo3) until the grips are holding the cartridge properly.

If the cartridge needs to be exchanged, it is necessary to slightly cut the sides of the grips with a box knife and re-move the cartridge by pulling the two now flexible grips outwards on each side of the EVS-insert with one hand and pulling the stainless steel cartridge from the EVS-insert with the other (Photo4). The o-ring will come out as well.

Before installing the replacement cartridge, the black composite part also needs to be replaced. Simply remove the composite part using a small piece of steel of brass bar or similar tool (ø10 mm and 150 mm length). Place the ancillary tool through the composite part (Photo5) and push down until the part loosens a little; no need to use much force. Then do the exact same thing from the opposite side of the part and the composite part is now free and can be easily removed from the EVS-insert by hand.

The new composite part is placed into the EVS-insert (Photo6). Please be aware of the two marks on each side of the composite part; these must fit into the two grooves on the EVS-insert. When in place, push the two parts together until they click and the EVS-insert is ready for use.

Same replacement procedure is used when renovating first-generation composite EVS-inserts. Procedure is very easy and can be done on site if necessary.

More Information

Latest News

See all

Upcoming Webinar

How to keep ΔT under control in high-load data centers

December 4th 2025, 13.00-13.45 CET

NEW SM actuator range for FlowCon SM PICVs

Wider flow range, new failure actions and programming port.

We say: the SAME but MORE

New massive T4 at Urumqi International Airport, China

Precise control, easy commissioning, scalability, efficiency, and lower operating costs is why FlowCon was selected

FlowCon publishes yet another EPD – now for PICV-actuators

The EPD covers the FlowCon FN, FH, FT, and SM ranges

Sustainability and PICVs

Sustainability in HVAC is no longer optional - it is fundamental to responsible system design